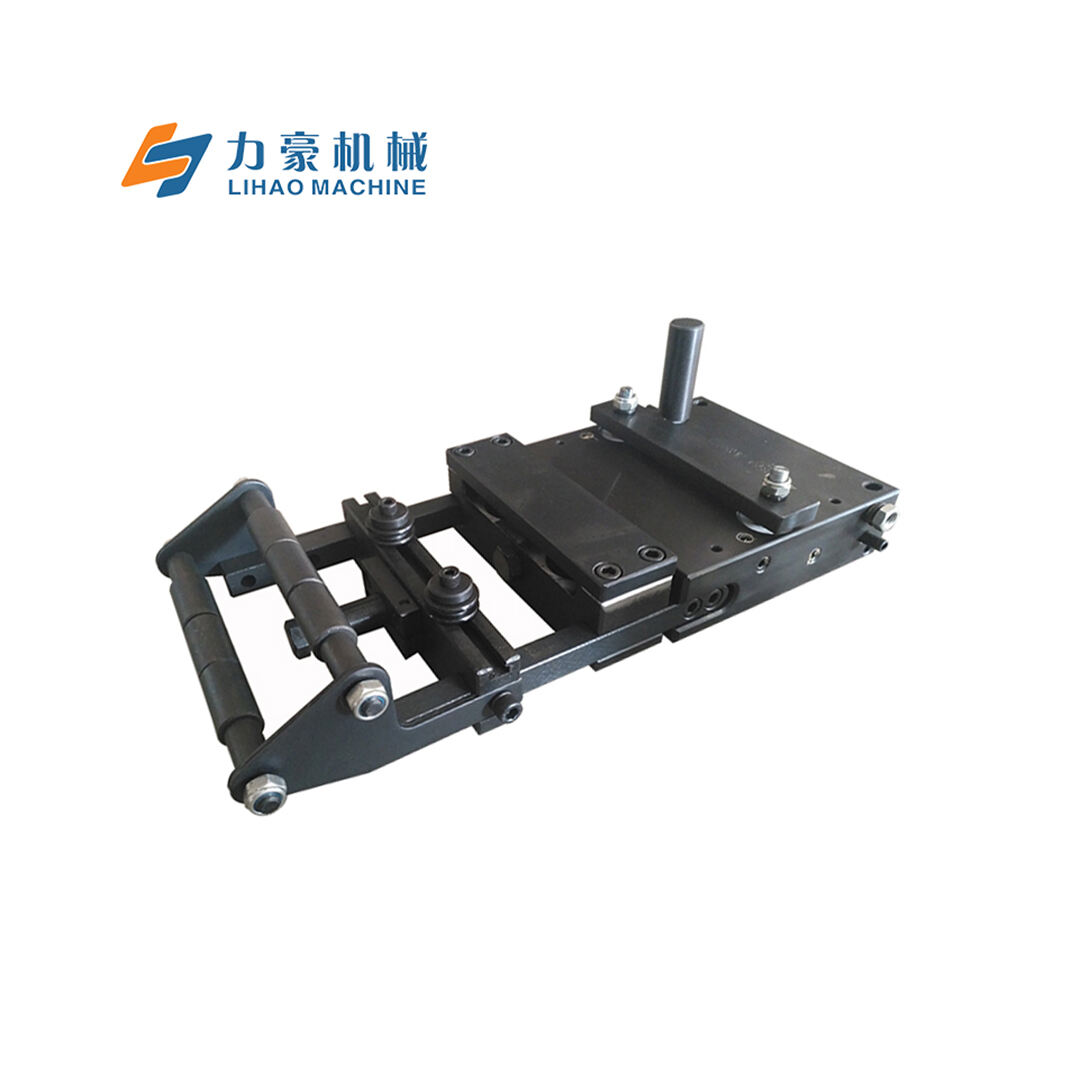

Air Feeders Tools Useful for Various Industries

Types of Air FeedersAir feeders continue to be invaluable across several industries like automotive, packaging and textiles. They are indispensable for lifting, sifting and storage of materials. Air feeders known for their design perfection, air feeder devices are ideal to use the components that have been playing a vital role in meeting modern production needs.

The Advantages of Air Feeders

Air feeders are used in a variety of situations and provide many advantages that can speed up the manufacturing process. These instruments also cut labor costs by simplifying the lines of production and enhancing productivity. As a result, this improves speed, accuracy and workflow.

Air Feeder Technology Latest Innovative Trends

It is also a fiercely competitive market and manufacturers are always looking to bring something new. Distinguishable companies dominate the industry by using cutting-edge technology to produce air feeding systems with better accuracy, quicker speeds and increased complexity.

Safety precautions for Air Feeder Systems

The manufacturers of the air feeder take care about both productivity and safety, with incorporation of exclusive features that creates a safer worksite protecting operators. Another common sign of dependable suppliers is a safety-first focus, meaning employees are safe through an adherence to the stringent international quality and safety norms.

Air Feeders in multiple Applications

Air feeders are versatile and find applications across industries. They are used in the automotive industry to convey metal parts along assembly lines. They help in easy transferring of products from one conveyor belt to another while packaging. Air feeders can also be adapted for feeding textiles to sewing machines in the textile sector.

Using Air Feeders Correctly

The operation of a pneumatic feeder is easy if properly complied with the techniques offered due to the maker. This typically includes detailed product documentation and customer support, to ensure that users are able to confidently operate the device.

Air Feeder Systems and the Importance of Quality

Long hours of operation in production lines require air feeders that are both inexpensive as well as reliable. Premium Original Equipment Manufacturers (OEMs) use high-quality materials, often from the best manufacturers and spend a lot of money on certification to perform better.

Different Uses of Air Feeders in Various Industries

Air feeders are used in different industries for a variety of functions, some air feeder designs serve specialized purposes (e.g., auto-decoiling) while others cater to more generic applcation requirements. A comprehensive range of air feeder models is available from top-level manufacturers to meet the particular demands of any client.

5 Oversea Branded Wholesale Air Feeder Suppliers

Pneumatic Feed Service: Reliable service providers with years of experience offers standardized products.

Coe Press Equipment - constant- and servo-driven coil reels, straighteners & feeds (push-pull air feed technology) precision in operation for 70 years; offers automation solutions to the industry.

Shung Dar Industrial Co., Ltd. (TAIWAN): Leading Taiwanese manufacturer dedicated in industry over three decades with vast experience of specializing in the production and launching Safe & Humanized Automatic NC Roll Feeders for nearly 400 sets per annum.

Decoiler Machine: A reputed Chinese manufacturer who produces top-rated air feeder systems and offers outstanding after-sales service.

Great Automation: Leading Malaysian manufacturer of high-speed air feeders for automotive use.

Choosing the right manufacturer is key to prevent your production line from break down. Air feeder manufacturer provide an all variety of new air feeders which are high-performance products manufactured with advanced technology, strict safety standards and superior product quality;