New Series NC Servo Roller Feeder with Pneumatic Release System for Feeding Metal Coils, Medium Plates, and Thin Sheets with Material Thickness: 0.2mm - 2.5mm

Advantage

-

Unique Japanese technology design

-

Reliability & rigid structure

-

High precision & durability

-

High Productivity

Product Description

· Features:

1. Suitable for feeding processing of materials with different thicknesses and varying lengths.

2. Suitable for high-speed and long-length feeding, enhancing productivity and feeding precision.

3. Simple operation panel with numeric keypad for setting feeding length and speed, allowing operators to quickly and accurately adjust as desired.

4. Utilizes pneumatic relaxation (precise relaxation points) for prolonged high-intensity use, resulting in low failure rates.

· Structure

1. Equipped with high-quality, brushless servo motor for efficient reduction of setup, adjustment, and testing time.

2. Incorporates high-sensitivity decoder for precise feedback, further enhancing feeding accuracy.

3. Synchronous belt drive eliminates gear backlash, minimizes wear, produces no noise, requires no lubrication, and ensures safety and environmental friendliness.

4. Motor is internally embedded to prevent damage during transportation and handling.

· Product Description

·Control panel

1. The human-machine interface adopts a 7-inch high-definition screen from Taiwan's Cermate, featuring uniform colors and delicate image quality. It is applicable to most industrial environments, boasting extremely high reliability, and supports synchronous communication via both serial port and network.

2. The switches utilize sliding contact design with self-cleaning function. The normally open and normally closed contact heads are structurally insulated, enabling bipolar operation. They are equipped with anti-rotation positioning and anti-loosening mounting pads.

3. Self-resetting push buttons are employed, featuring lightweight operation and moderate keystroke. The modular combination structure utilizes ketone-based composite points for the contacts, ensuring strong conductivity and high current carrying capacity, with a lifespan of up to 1 million cycles.

·Operating handle

1. The electrical control box is equipped with a separate operating panel, facilitating personnel rotation for operation, saving time, and featuring waterproof and dustproof properties. Constructed with high material strength and excellent conductivity, it boasts a long lifespan.

2. The electrical control box is separately equipped with an emergency stop button, ensuring safety and reliability while effectively reducing the frequency of electrical control box opening and closing, thus safeguarding the operation panel effectively.

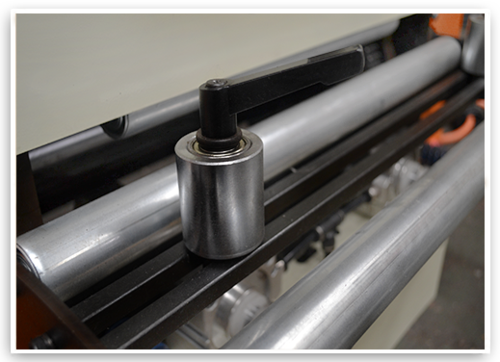

·Feed roller, retaining wheel

1. The feeding rollers utilize passive galvanized rollers, integrally formed, featuring a surface resistant to scratching and abrasion. Equipped with mechanical bearings, they offer flexible rotation and long-lasting durability.

2. The feed-in guide wheels undergo hard chrome plating treatment, with a hardened chrome layer reaching HRC60 after quenching. The locking handle provides strong clamping force and convenient locking, ensuring smooth rolling of the rollers.

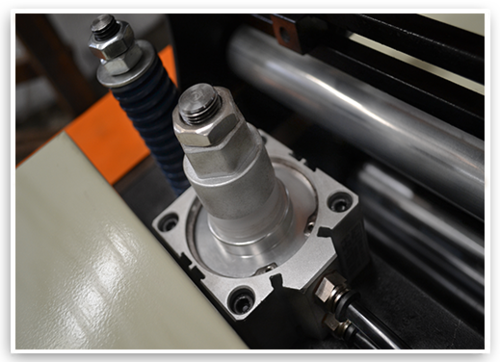

·Feed cylinder

Utilizing genuine Yadeke pneumatic cylinders, featuring alloy cylinder bodies with hard oxidation, ensuring leak-free riveting. Solid aluminum undergoes CNC precision machining, with internally polished walls for smooth operation, high efficiency, and resistance to jamming. Capable of high-intensity operation, it is durable and suitable for various working conditions.

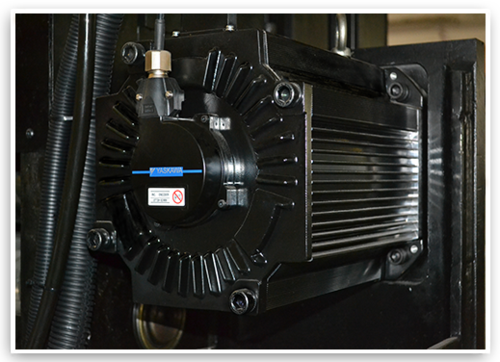

·Servo motor

Both the servo motor and driver utilize the Yaskawa brand (optional), significantly enhancing equipment performance, maximizing device capabilities, and solving challenges. Yaskawa's innovative "no adjustment function" is further developed, eliminating the need for cumbersome tuning operations. With stable movements, it can be used in harsh environments, saving energy, complying with safety standards, and achieving visualization.

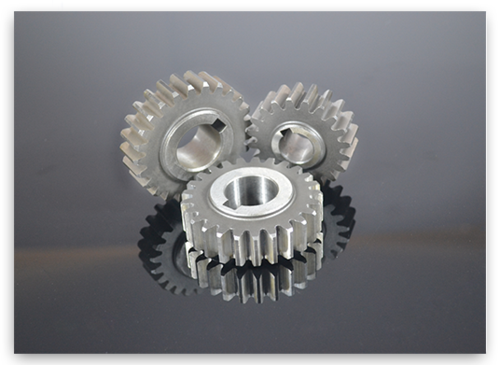

·Transmission gear

The gear manufacturing process includes the following steps: Gear rough forging - Gear tooth surface machining - Heat treatment - Gear tooth surface grinding. The rough forging is primarily done using forgings, undergoing normalizing to improve its machinability, facilitating cutting. Following the gear design drawings, rough machining is carried out, followed by semi-finishing, involving hobbing, shaping, and broaching to achieve basic gear formation. Subsequently, heat treatment is performed to enhance mechanical properties. According to the drawing requirements, final finishing is conducted, refining the standards and gear tooth profiles. Through these processes, our gear reaches Grade 6, boasting high wear resistance, high strength, and long service life.

· Specification table:

|

Model |

Material thickness |

Material width |

|

NC-200 |

2.5mm |

200mm |

|

NC-300 |

2.5mm |

300mm |

|

NC-400 |

2.5mm |

400mm |

|

NC-500 |

2.5mm |

500mm |

|

Model |

Material thickness |

Material width |

|

NC-200A |

3.2mm |

200mm |

|

NC-300A |

3.2mm |

300mm |

|

NC-400A |

3.2mm |

400mm |

|

NC-500A |

3.2mm |

500mm |

· Configuration table:

|

Name |

Brand |

Model |

|

Bearing |

HRB、ZWZ |

6206、6207 |

|

Servo motor |

Zhejiang Dongling |

1.5kw |

|

HMI |

Paneimaster |

SA2070 |

|

PLC |

Mitsubishi |

FXIS-14MT |

|

Electromagnetic valve |

Guangdong Punan |

4V310-10 |

|

Cylinder |

AirTAC |

SDA-60*10-N |

|

Transformer |

Dongguan Jinhuan Long |

2KVA |

|

Proximity switch |

Meanwell |

SN04-N |

|

Switch |

Meanwell |

50W |

|

Relay |

Omron |

MT2 |

|

Main switch, Contactor, Push button switch, Indicator light, Insurance |

CHNT |

- |

· Applications

The NC Servo Roller Feeder is suitable for high-speed fixed rotor stamping production lines, heat exchanger stamping production lines, brake pad and friction sheet production lines, hardware parts stamping production lines, radiator production lines, and more.

· Package

Based on the specific characteristics of different products, packaging should be as follows, if necessary:

1. Utilize plywood at the bottom for strong waterproof performance.

2. Protect corners with foam and secure with protective film.

3. Cover entirely with robust, hard protective film.

4. Include internal steel frame protectors.

5. Use plywood packaging.

6. Complete packaging with standard containers or frame containers.

· LIHAO Pre-Sale Service

1. Customized Equipment: Based on the technical parameters of the application-related equipment provided by the customer, we can modify our machines to meet the customer's convenience and high production efficiency.

2. Solution Design: According to the customer's product processing requirements, we design unique solutions to support higher manufacturing efficiency and better processing quality.

· LIHAO After-Sale Service

1. As a professional manufacturer and supplier of automation machines, LIHAO provides English training videos and user manuals for all machines, covering installation, operation, maintenance, and troubleshooting. Additionally, we offer technical guidance through remote means such as TeamViewer, email, phone, mobile, WhatsApp, Skype, and 24/7 online chat when you encounter issues with installation, operation, or adjustments.

2. Customers can choose to come to our factory for 2-5 days of training. We will provide professional guidance and effective face-to-face training.

3. Our engineers will provide on-site guidance and training services at your location. We will require your assistance in arranging visa procedures, prepaying travel expenses, and accommodating us during the business trip and service period.

· Lihao Automation Feeder Machine Guarantee

1. The entire coil feeder machine is covered by a 1-year free warranty.

2. Lifetime maintenance is provided, with our after-sales department offering 24/7 online support.

3. We offer machine-related parts services. After the 1-year warranty period, buyers will need to pay for repair parts.

· Shipping to Around the World

All machines can be shipped worldwide via sea, air, or express logistics through DHL, FedEx, and UPS. You are welcome to obtain a free quote by filling out the form with your name, email, detailed address, product, and requirements. We will promptly contact you with complete information, including the most suitable delivery method (fast, secure, discreet) and shipping costs.