LIHAO stands at the forefront of the metal stamping industry, providing advanced solutions tailored to your press line requirements. Specializing in the equipment R&D, manufacturing and sales of complete stamping lines, we cater to a wide variety of material specifications, including type, thickness, yield strength, width, and weight.

Contact-us

1.Production Line Features

This production line significantly reduces labor costs and improves production efficiency. Before the improvement, it required 7 operators, but now only 1 person can complete all operations. The product flatness reaches ±0.5mm, angles reach 90º±0.5º, hole positions meet the requirement of ±0.1mm, the automatic welding torque strength is not less than 50N/M, the layout of the line meets the requirement of over 95% accuracy in dimension positioning, product tolerance is within ±0.2mm, and the production cycle is between 3 to 6 seconds per piece.

2.Production Process

Sheet metal coil - Uncoiler - Straightener - Feeder - Punching - Spot welding - Bending - Product center

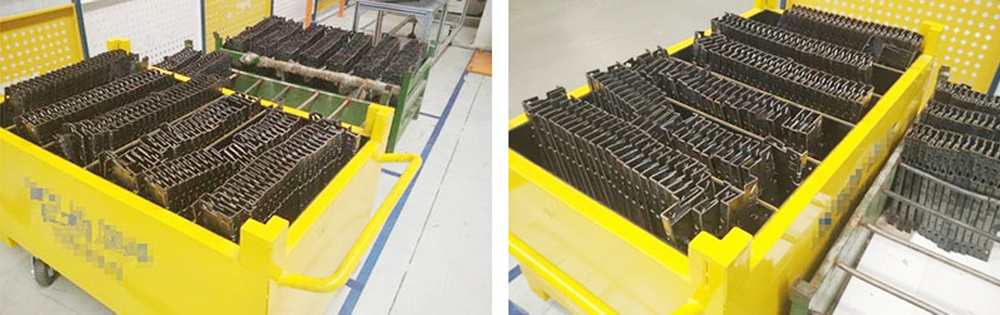

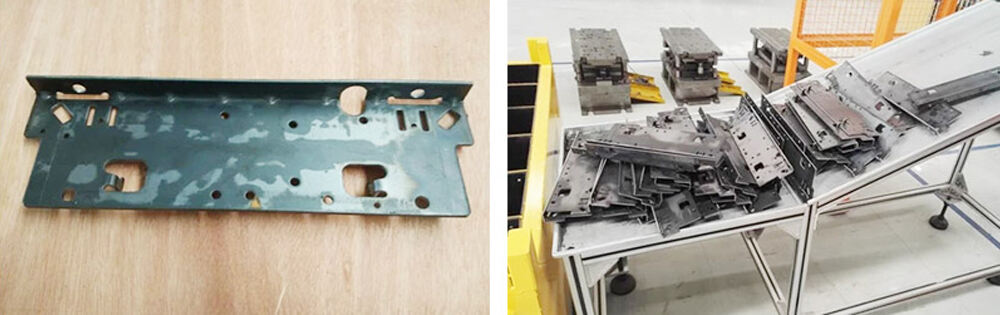

3.Finished Product

4.Details of Machine

NCSF-600B: This is a large machine with a 3 in 1 sheet metal coil feeding system, integrating the functions of uncoiler, straightener, and NC servo feeder.

5.Suitable Materials

Metal

6.Video

Press Feeding Line For Automotive Industry Working Video: Click here