When press forming sheet metal on a punching machines, the feeder pushes material into the die space. During stamping, the sheet goes from the elastic state to its plastic state, where the sheet stays bent. The bend angle is set as a function of the depth of penetration into the die space, with the inside bend radius nearly equal to the material thickness, depending on the die width.

Contact-us

1.Production Line Features

We offer a complete production line solution, including stamping molds, covering the entire manufacturing process from raw material to the finished product.

2.Production Process

Sheet Metal Coil-Uncoiler-Straightener-Feeder-Press Machine-Mold-Product

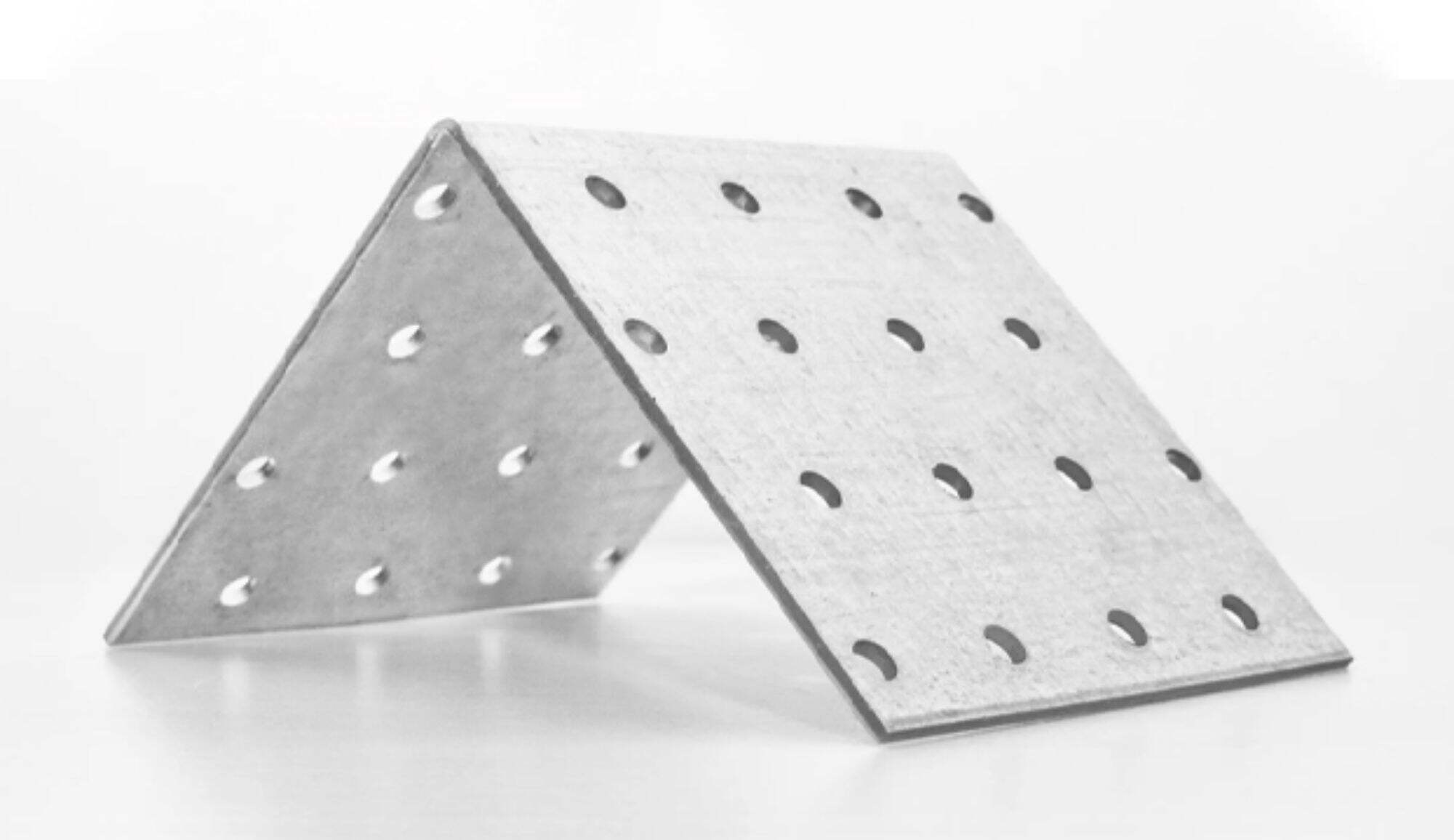

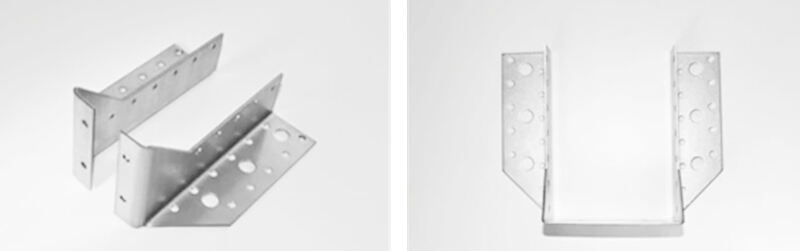

3.Finished Product

4.Details of Machine

- GO Series Decoiler & Straightener 2 IN 1 Machine: This integrated machine combines decoiling and straightening functions, saving space and ensuring ease of operation.

- NCF Servo Feeder: Designed to handle materials of various thicknesses and lengths, enabling flexible processing capabilities.

- JH21 Press Machine: A high-performance press machine powered by pneumatic force, ensuring efficient and reliable operation.

5.Suitable Materials

Our equipment is suitable for processing various types of metals, providing versatility to accommodate different material requirements.

6.Video

V Bending Process Video: Click here