Давным-давно, на сталелитейных заводах рабочие производили огромные и тяжелые катушки стали. Эти катушки были чрезвычайно громоздкими и жесткими, что делало их неудобными для транспортировки и использования на заводах. Из-за этого многим людям было трудно работать с такими большими катушками. И тогда у кого-то возникла отличная идея, Лидао режущая машина . Этот новый метод произвел революцию в использовании стали на заводах.

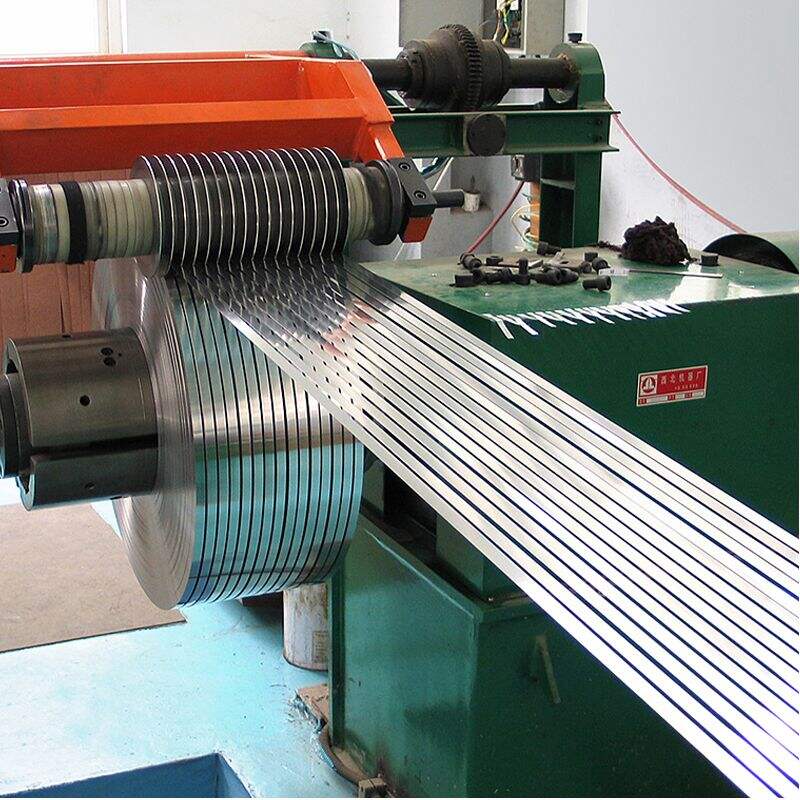

Итак, что же мы подразумеваем, говоря о раскрое стального ката? Это процесс, при котором большие и гораздо более тяжелые каты стали режутся на управляемые, меньшие части. Сначала большой кат стали аккуратно разматывается. Затем он направляется через специальную машину с круговыми пилами. Эти пилы действуют как огромные пиццерезки, разрезая большой кат на более узкие полосы. На машине обработка остывшей стали имеет множество вариантов, которые люди создают для работы. После раскроя более узкие каты снова сворачиваются, что значительно упрощает их использование в различных задачах.

Предприятия и промышленные объекты, использующие сталь в рулонах, получают много преимуществ различными способами. Во-первых, сталь разрезается на более мелкие рулоны, которые значительно удобнее транспортировать и хранить. Маленькие рулоны занимают меньше места и лучше помещаются в грузовики. Во-вторых, можно сэкономить на транспортных расходах, уменьшая большие рулоны до маленьких. Маленькие рулоны помещаются в небольшие грузовики, поэтому они потребляют меньше топлива при перевозке. Это выгодно как для вашего бюджета и расходов на топливо, так и для окружающей среды, поскольку используется меньше топлива. В-третьих, с маленькими рулонами безопаснее работать. Работники меньше подвержены риску травм, так как могут легче маневрировать маленькими рулонами. Наконец, используя маленькие рулоны на заводах, можно производить именно то, что нужно клиентам. Это означает, что продукция может соответствовать конкретным заказам и потребностям.

Машины, работающие на Lihao продольная резка стального рулона просто великолепны, так как они создают очень точные резы. То есть, вся ленточный рез из катушки имеет одинаковый размер и качество, что является важным в производстве. Если полосы абсолютно одинаковы по своей природе, это способствует улучшению качества продукта, изготавливаемого из них. Кроме того, этот процесс минимизирует образование отходов, позволяя получать меньше непригодного остаточного материала. На самом деле, технология, используемая для продольной резки стальной катушки, может резать даже специальные формы. Это отлично подходит для создания деталей продуктов, таких как автомобильные детали, поскольку им часто нужно иметь определенную форму, чтобы они могли правильно соединяться.

Возможно, самая захватывающая сторона Lihao цена машины для продольной резки стальных катан заключается в его потенциале минимизировать отходы. Термин «выход» относится к доле стали, которая при производстве изделий действительно используется, по сравнению с той, которая идет в отходы. Старые методы производства стали оставляли много отходов, потому что сталь производилась в огромных рулонах, которые нужно было разрезать на заготовки. В результате процесса образовывалось значительное количество металлического лома, который выбрасывался. Однако при продольной резке рулонной стали она сама разрезается на более мелкие катушки, что помогает устранить отходы. Это позволяет более эффективно использовать сталь, экономя деньги и делая производственный процесс более эффективным.

Однако со временем станок для продольной резки листовой стали были улучшены и достигнуты успехи. Некоторые из самых современных машин теперь оснащены компьютерными системами, которые могут выполнять сложные резы автоматически, без необходимости постоянного присутствия человека. Некоторыми другими улучшениями являются лазеры или другое высокотехнологичное оборудование, которые помогают сделать рез максимально точным и равномерным. Быстрая работа машин означает быстрое и безопасное производство с минимальным присутствием рабочих рядом с машинами.

Это одна из лучших в линия размотки машины . Это их специализация, и у них есть технологии, позволяющие производить продукцию для множества отраслей промышленности. Среди них — автомобилестроение, строительство и машиностроение. Методы работы компании демонстрируют их приверженность инновациям и удовлетворению потребностей клиентов. Компания оснащена современным оборудованием для продольной резки рулонной стали и обладает гибкостью для изменения производственных циклов в соответствии с требованиями клиентов.

Мы являемся специалистами в области машиностроения и разработки долговечного инструментального оборудования, при этом минимизируя необходимость настройки оборудования и количество брака. Наши станки для продольной резки рулонной стали обеспечивают глобальный пуск в эксплуатацию и обучение персонала, что гарантирует бесперебойную интеграцию и оптимальную производительность по всему миру. Мы обеспечиваем максимальную эффективность, сводим к минимуму простои в вашем собственном производстве, поставляем детали высокого качества и оказываем техническую поддержку. Будучи сертифицированными по стандарту ISO 9001:2000 и имея знак соответствия ЕС (CE), мы поддерживаем самые высокие стандарты качества продукции.

Lihao Machine предлагает индивидуальные решения, а также полный комплекс услуг для удовлетворения разнообразных потребностей ваших клиентов. Предлагая множество продуктов, таких как трехвальные податчики Decoiler Cum Straightener машины, NC сервоподатчики и пресс-машины, мы предоставляем полный спектр услуг, охватывающих производство, проектирование, продажи, обслуживание и торговлю. Наша команда R&посвященная D обеспечивает возможности кастомизации и технические консультации, гарантируя, что каждый продукт адаптируется под ваши конкретные потребности.

Наша преданность инновациям, улучшению и постоянной надежности товаров и услуг неизменна. Группа Lihao очень искусна в предоставлении передовых решений. Мы являемся настоящим первым выбором для автоматизации штамповки. Мы ставим высшую цену на удовлетворенность клиента, предоставляя высококачественное оборудование и образцовые услуги каждый раз.

За более чем 26 лет лидирующего положения, компания Lihao Machine является ведущим поставщиком на внутреннем и международном рынках. Наши продукты используются во всем мире. Вы можете рассчитывать на наших клиентов по всему миру с более чем 20 офисами по всей Китае и филиалом в Индии. Мы предлагаем индивидуальные решения во многих отраслях благодаря нашим значительным технологическим возможностям.