Stamps - What Are They and How Do They Work?

Stamping is an incredible process that offers the capability to manufacturers for producing unique designs and logos on different metals. Stamping is the process of transferring your design to metals that will be there and look crisp cleanly forever. We are going to analyze it further and why stamping by Lihao is a number one choice of many manufacturers due the advantages, innovations, applications quality and usage.

Advantages of Stamping

The stamping process, is primarily centered around the skill of pressing an original pattern (or logo) into metal and guarantee its wear-resistant over a performance time frame of the component. This is where the primary advantage of stamping comes -- and that's to fulfill this goal. Users can burn their emblem on different metals such as copper, aluminum, brass including gold silver and stainless steel. This makes it easy for companies to personalize the products and create brand differentiation. Stamping Die is also cost-efficient, quick and precise. Once a stamping die is installed, it can be used many times. Stamping allows for the production from patterns to small unique numbers or logos.

Innovation in Stamping

In fact, the rapid developments in technology have since catalyzed a lot of proprietary and next-generation innovation on stamping. This also allows businesses to digitally replicate much more detailed and elaborate forms at different sizes with all their proportions. Top-quality machinery for progressive stamping is designed to create an impression of different metallic materials with expedited precision. Digital imaging processes have made it practical to create intricate designs that can be embossed on metal.

Safety and Use of Stamping

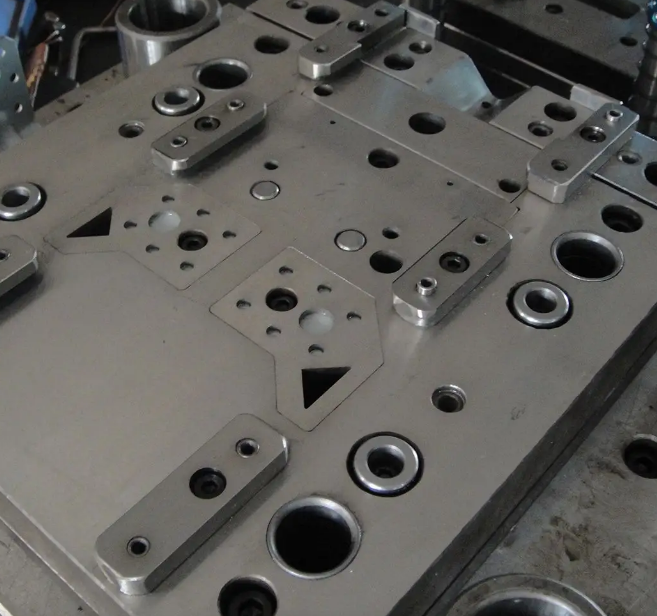

Stamping is also famous for safety, little insecurity to personal well-being. The first things to deal with are the materials of that equipment you have during pressing, followed by injuries prevention. Manufacturers and companies can do well to these risks substantially, if they impart appropriate instruction and uphold safety practices. A metal stamping dies (a custom metal plate that is a mold and perforated to form the desired design) must be used this process started This die is then pressed against the metal, creating a long-lasting and crisp impression. From jewelry to automotive components, electronic parts and so on, stamping plays a part.

How to Use Stamping

Stamping work starts with the designing of what you are going to imprint. Additionally, a stamping die with the desired pattern is configured. A metal strip is placed below a stamping die and the press applies the large force to push down that causes this design of filigree on its felt.

Service and quality of stamping

When it comes to businesses that provide stamping solutions, not only do they claim to have everything; the fact of appearance also sides using them. The Stamped Project: The finish quality of a stamped project is almost entirely dependent on the design, instruments employed, and operator's level. The great majority of the stamping manufacturers tend to provide a superior design, and result followed by fast turn around times. Many businesses go a step further and provide solutions that are personalized so as to fulfill the criteria of their clientele, by way of instance the maturation in grooming services.

Application of Stamping

Use of stamping is seen a large number to industries for creating custom art work and positioning brand image. Stamping finds a key role in the automotive industry by shaping car body parts, engine components and various other important mechanical features. The electronics industry uses stamping to manufacture such items like connectors, pins, clips and brackets. Furthermore, the jewelry industry uses stamping for customization of jewelry in exclusive designing.

Stamping, in simple words a unique way which empowers the manufacturers to produce various designs and logos on different metals. You certainly benefit from this method, because it is economic to use, accurate and definitely safe. The main reasons why 3D printing are widely applied in various spheres including car industry or electronics as well polishing the jewelry. Stamping is a technical process which has developed along with the technology, and it develops hand in hand with other industries.