Introduction: What is Progressive Stamping?

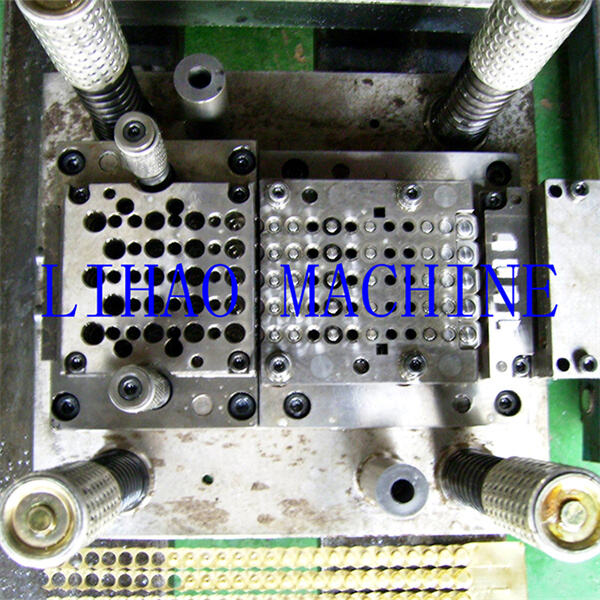

Progressive stamping is a manufacturing process that involves using specialized machines to create complex metal parts. This Lihao progressive stamping process is often used in the automotive, aerospace, and electronics industries to produce too parts difficult to create using traditional manufacturing methods. By using progressive stamping, manufacturers can produce high-quality parts quickly and efficiently.

There are many advantages using progressive stamping. One of the main benefits of the Lihao metal stamping dies is that it is a cost-effective way to produce large volumes of parts. This is because the process can be automated, which reduces the need for manual labor. Another advantage is this a very precise method of manufacturing. This means that parts produced using this process are very accurate and have a high level of consistency.

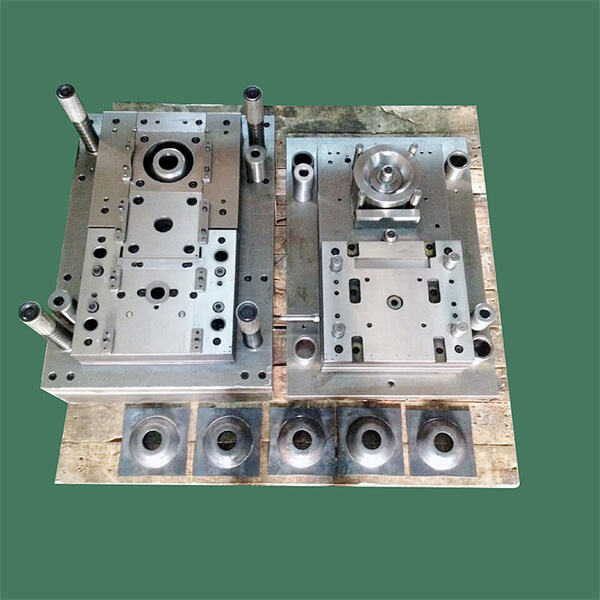

In recent years, there have been many innovations in progressive stamping. One of the most significant innovations of Lihao steel stamping dies has been the development of new materials that can be used in the process. For example, manufacturers can now use lightweight materials like aluminum and titanium to produce both parts strong and lightweight. Another innovation is the use of advanced software to control the manufacturing process. This allows manufacturers to produce parts with a high level of precision and accuracy.

Safety is a critical factor in any manufacturing process, including progressive stamping. Manufacturers must take steps to ensure that their workers are safe when operating the equipment. The Lihao die stamping press includes using safety guards and other protective equipment. It is also essential to train workers on how to use the equipment safely and to provide ongoing training to ensure that they stay up-to-date with the latest safety protocols.

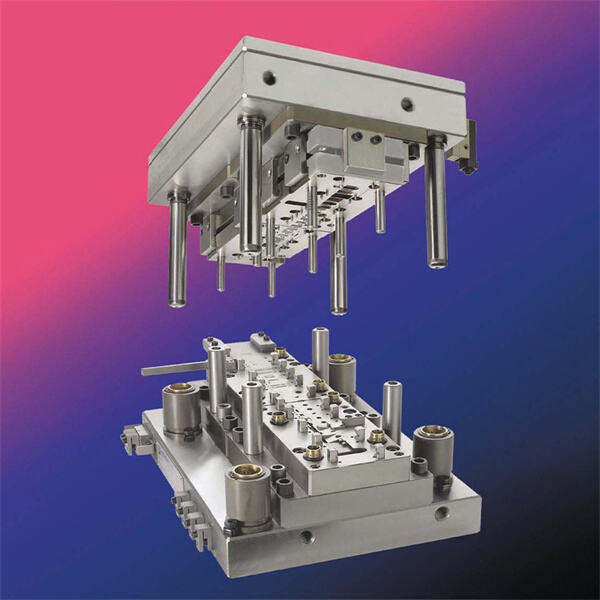

Using progressive stamping requires specialized equipment and expertise. Manufacturers of the Lihao stamping mould have an access to high-quality stamping machines and other equipment, as well as skilled workers who are trained in how to operate the equipment. To use progressive stamping, must follow a manufacturers precise set of steps, including designing the part, creating the stamping tool, and setting up the machine.

Lihao Machine offers tailored solutions and complete services to fulfill different customer. We offering integrated services that encompass design, manufacturing and sales. Our committed R&D team will provide your with personalized alternatives and technical discussion guaranteeing each solution is perfectly customized to satisfy your own needs.

Our dedication to quality, reliability and continual improvement of products and service is an ongoing procedure. Our Lihao team is highly skilled and offers cutting-edge solutions. We are the true number one solution in stamping automation. We place great importance in ensuring consumer satisfaction by consistently supplying the quality highest products plus services.

Our company is specialists in engineering and design that is robust of, which helps in reducing alterations to setup and scrap production this is certainly decreasing. Our progressive stamping offer worldwide training and commissioning, ensuring the performance which was highest and integration that is seamless the whole world. With our own manufacturing business and high-quality spare parts support we could guarantee minimum downtime and productivity which are high. Our company is ISO9001:2000 certified in addition to EU CE approved.

Lihao machine has been a leader on the market since 1996. It had been a reliable supplier regarding the national and international markets. Our items are used throughout the selection of industries around the world. We offer our clients worldwide with more than 20 offices in China additionally the branch in India. Our robust technological capabilities enable customized solutions for a variety of industries.