Stamping mold production line

More and more customers are considering cost saving. From purchasing products to deciding to purchase production equipment, LIHAO Machinery provides stamping automation production line services. We have helped many domestic and foreign customers design their own production lines. Today we briefly introduce the composition of the button press production line.

The button production line usually includes the production of corns, five claws, snap buttons and other products. Different products are produced by changing molds.

Generally, button products are basically equipped with high-speed presses in consideration of high efficiency, and usually the entire line includes the following equipment.

1. Flat material rack.

The flat material rack is suitable for high-speed unwinding, and multiple rolls of material can be put on it at one time, which saves time for material changing and ensures uninterrupted production.

2. High-speed roller feeder.

The high-speed roller feeder is used in conjunction with the high-speed punch, and is connected with the punch through the punch output shaft. The power source is the punch, with low failure rate and high production efficiency.

3. High-speed punch

The high-speed punching machine has a higher working speed than ordinary punching machines, the number of strokes of the punching machine can reach 200-600 times per minute, with high working efficiency and high output.

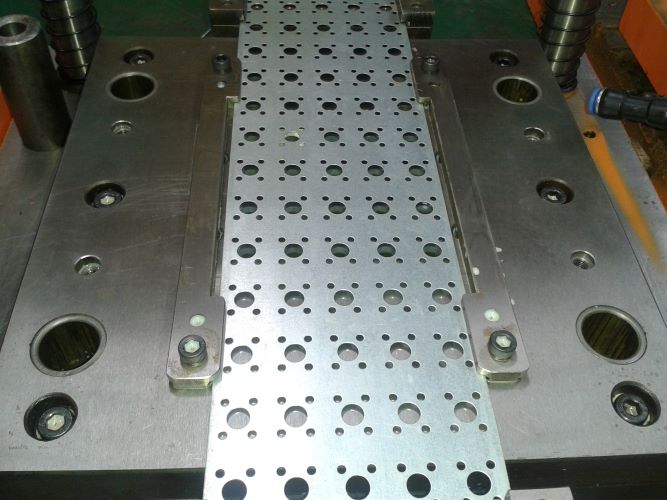

4. Mould

The mold can be designed according to the customer's product and output requirements: one mold, two molds, three molds and so on.

LIHAO Machinery has rich experience in production design and can design suitable production according to customer needs