What's Three-in-One Uncoiler Straightening Feeder?

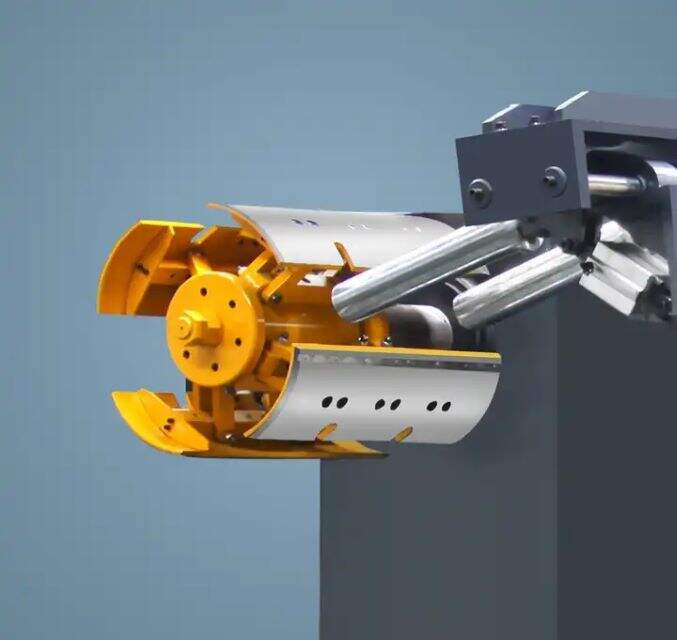

The Metal Three-in-One Servo Feeder combines three essential mechanical components: the decoiler, straightener and feeder. This integrated system is designed for efficient metal processing. The uncoiler facilitates material unwinding, while the straightener ensures precise leveling of the metal sheet. The feeder completes the trio, managing the continuous and accurate feeding of the material for subsequent processing. This versatile equipment streamlines the production process, offering a comprehensive solution for metalworking needs.

Introduction to 3 in 1 Servo Feeder Machines

The Metal Three-in-One Servo Feeder seamlessly integrates three essential functions: decoiling, straightening, and feeding. This integrated system is specifically designed for efficient metal processing. The decoiler facilitates material unwinding, while the straightener ensures precise leveling of the metal sheet. The feeder completes this trio by managing the continuous and accurate material feeding for subsequent processing. This versatile equipment simplifies the production process, providing a comprehensive solution to meet the diverse needs of metalworking. making it versatile for a wide range of applications in the metal processing industry.

The Three-in-One Servo Feeder finds application across various industries and processes.

Automotive Industry:

Precision feeding of metal sheets for car body parts manufacturing.

Coil processing for the production of automotive components.

Electrical Industry:

Feeding and processing of metal sheets for the fabrication of electrical enclosures.

Coil handling in the manufacturing of electrical panels and components.

HVAC:

Continuous and accurate feeding for the production of HVAC system components.

Coil processing for air duct fabrication in HVAC systems.

Roofing:

Efficient feeding and processing of metal sheets for roofing material production.

Coil handling in the manufacturing of metal roofing components.

Coating Industry:

Precise material feeding for the coating of metal sheets in various applications.

Continuous processing of coils for coating and finishing purposes.

Advantages of three-in-one servo feeder

1. High-Precision Servo Control: The Metal Three-in-One Servo Feeder utilizes advanced servo control technology to guarantee high-precision positioning and motion control during feeding, decoiling, and straightening processes. This significantly enhances production efficiency and product quality.

2. Multifunctionality: The equipment integrates three critical functions - feeding, decoiling, and straightening - addressing diverse metal processing needs. Users can effortlessly switch and adjust the machine's operating modes according to different production tasks.

3. Automation and Intelligence: Equipped with advanced automation and intelligence features such as automatic feeding, and remote monitoring, the Metal Three-in-One Servo Feeder reduces manual intervention, thereby improving production efficiency and workplace safety.

4. Efficiency and Energy Saving: The machine incorporates advanced energy management technology to optimize energy consumption, enhance energy utilization efficiency, and reduce operational costs.

5. Stability and Reliability: Subjected to rigorous quality control and testing, the Metal Three-in-One Servo Feeder offers stable and reliable performance, ensuring its suitability for prolonged and large-scale production requirements.

6. Flexible Adaptability: Suitable for processing various metal materials, including steel, aluminum alloys, copper, and more. Additionally, it accommodates workpieces of different shapes and sizes, demonstrating strong production adaptability.

Selecting the Right Three-in-One Servo Feeder

When choosing a metal coil decoiler, straightener, and feeder based on your specific requirements, consider factors such as coil size, material thickness, production output, and available space. Additionally, assess whether your application requires additional features, such as a coil cart for easy loading or a loop control system for tension management.

Maintenance and Care

Proper maintenance is crucial to ensuring the longevity and optimal performance of the Three-in-One Servo Feeder. Regularly inspect and lubricate components, check for wear, and adhere to the manufacturer's recommended maintenance schedule to prevent downtime and costly repairs.

Conclusion

The Three-in-One Servo Feeder serves as a multifunctional powerhouse, significantly enhancing efficiency and productivity across various industries. Understanding their applications, advantages, and types is crucial in selecting the right machine to meet your specific production requirements. Whether you're in metal manufacturing, construction, automotive, or any other industry reliant on sheet metal processing, a carefully chosen Three-in-One Servo Feeder can be a transformative asset, streamlining your production operations.