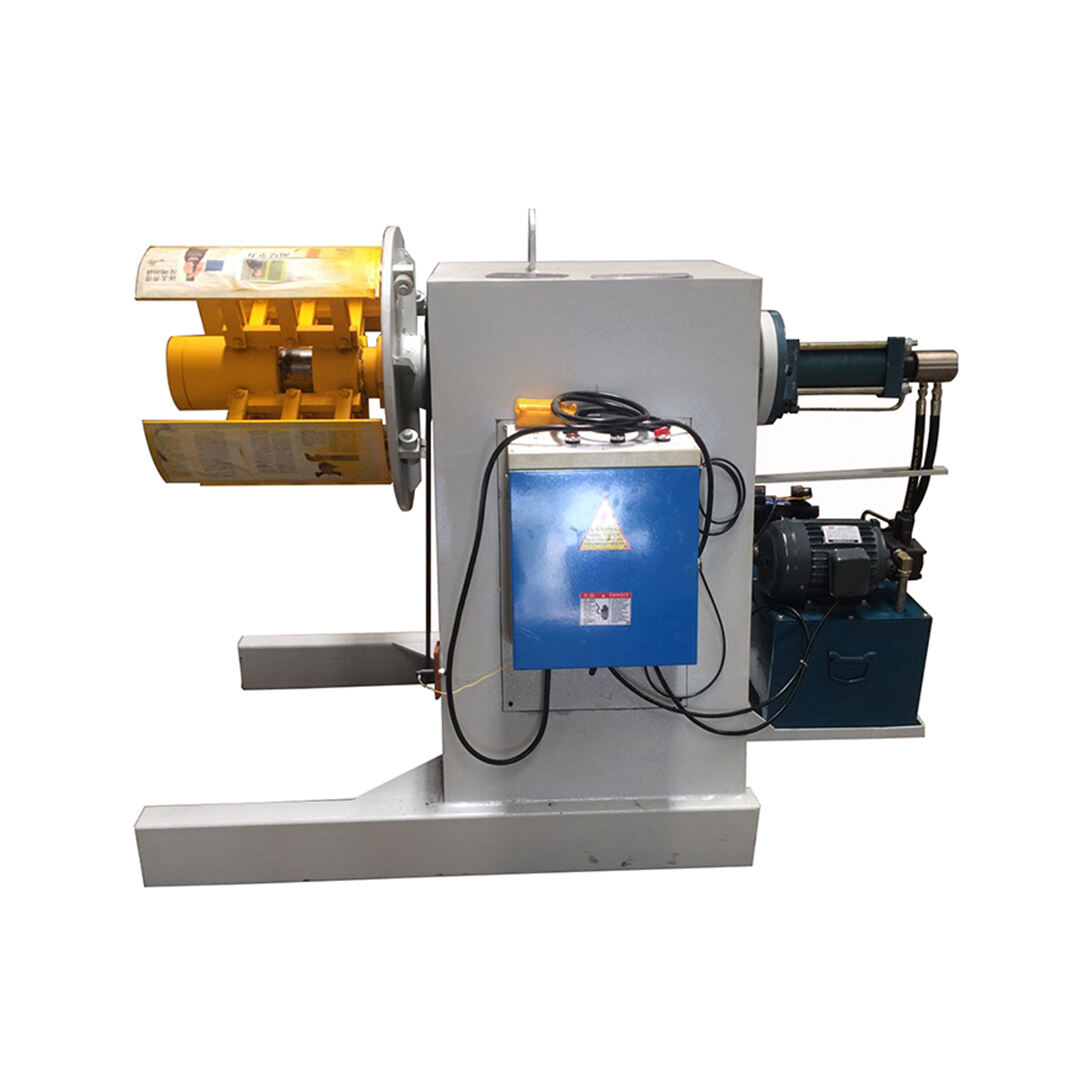

MT Series Heavy-Duty Material Rack Metal Sheet Automatic Uncoiler, Material Width Suitable for 200mm - 800mm

Share

Features

1. Suitable for all kinds of coil material feeding.

2. It can work together with straightener ,buyer can also choose non motive power style.

3. Customized Maximum load weight is 30T

4. Customized Maximum material is 1800mm.

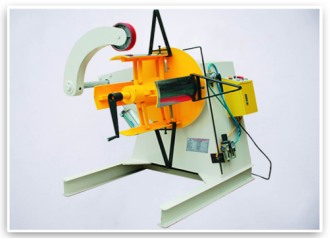

Options device

1、Pressing arm

2、Hydraulic expansion

3、Hydraulic support feed device

4、Motor can be speed adjustable style

Product Description

Description:

Our reel design features an innovative "bearing tube" equipped with dual cup and cone Timken bearings to the mandrel, supported by a robust cabinet base. Depending on your needs, we offer both motorized and pull-off type reels.

Standard configurations include single-end setups, while double-ended configurations can be provided to streamline production and minimize coil changeover time. Additionally, most models can be customized as Traveling Reels with automatic centering capabilities.

We offer tailored engineering solutions to meet the unique demands of any application.

Product Features:

1. Suitable for feeding various coil materials.

2. Can be used in conjunction with straightening machines, with the option of a non-powered version.

3. Maximum load capacity can be customized up to 30 tons.

4. Maximum material width can be customized up to 1800mm.

Optional Special Devices:

1. Material pressure arm.

2. Hydraulic expansion method.

3. Hydraulic material support and feeding device.

4. Motor can be equipped with variable speed control.

Rack section

1. The frame is designed with welded construction, using dual-protection welding machines for welding. Welding starts with welding the vertical corners, followed by welding the flat corners. Short seams are welded first, followed by long seams, ensuring tight welds and enhancing quality.

2. All frame materials are cut using laser or plasma cutting, resulting in high precision.

3. All parts are machined using CNC and numerical control technology, ensuring good interchangeability of equipment.

4. The overall structure is simple, allowing assembly and replacement of equipment parts by general technical workers, making it convenient and quick, significantly reducing maintenance costs.

Main shaft、tile part

1. The tiles are made of A3 material, undergo deburring after cutting, followed by milling of tile chamfers, and then proceed to bending, drilling, and milling groove processes.

2. Anti-slip nuts are used to secure all components, preventing loosening during operation, thereby avoiding machine damage or injury incidents.

3. Both the main spindle screw and screw sleeve are precision machined to ensure smooth adjustment of the machine's inner and outer diameters, thus avoiding unnecessary downtime for adjustments.

Power section

1. Employing an 80-type worm gear vertical reducer, utilizing the gear speed converter, to reduce the rotation speed of the motor to the desired speed and achieve a mechanism with higher torque.

2. Utilizing a vertical motor, with low vibration and noise. The stator part adopts pure copper coils, with a lifespan ten times that of ordinary coils. Equipped with ball bearings at both ends, resulting in low friction and temperature.

Electric control box

1. Utilizing silver alloy relays, all-copper coils, flame-retardant safety bases, ensuring long-lasting durability.

2. Employing safety-protected adjustable circuit delay relays with silver alloy contacts and multiple range discs, meeting various delay requirements.

3. Switches feature sliding contacts with self-cleaning function. Normally open and normally closed contacts adopt a split-coupled structure, allowing bipolar operation, with anti-rotation positioning and anti-loosening mounting pads.

4. Utilizing self-resetting flat buttons, light and agile in operation, with moderate keystroke. The contact blocks employ ketone-based composite points, providing strong conductivity and capable of carrying large currents, with a lifespan of up to 1 million cycles.

Non-standard custom one

1. The equipment's material width can be customized according to requirements, currently up to a maximum of 1800mm wide.

2. The inner and outer diameters of the material rack can be customized as needed, with a maximum size of up to 1500mm.

3. It can be equipped with a material pressure arm to prevent coil disintegration, or a variable frequency drive for speed control.

4. Hydraulic station can be installed for hydraulic expansion, providing convenience, speed, and ensuring expansion is in place.

Specification:

| Type | Material width (mm) | Coil.I.Dia (mm) | Coil.O.Dia (mm) | Coil Weight (kg) |

| MT-200 | 200 | 450-530 | 1200 | 500 |

| MT-300 | 300 | 450-530 | 1200 | 800 |

| MT-400 | 400 | 450-530 | 1200 | 1000 |

| MT-500 | 500 | 450-530 | 1200 | 1500 |

| MT-600 | 600 | 450-530 | 1200 | 2000 |

| MT-800 | 800 | 450-530 | 1200 | 2000 |

Standard Feature:

Motorized and Non-Motorized type of decoiler are available.

Line speed 16m/min

Loop touch stand

“A” frame coil keeper