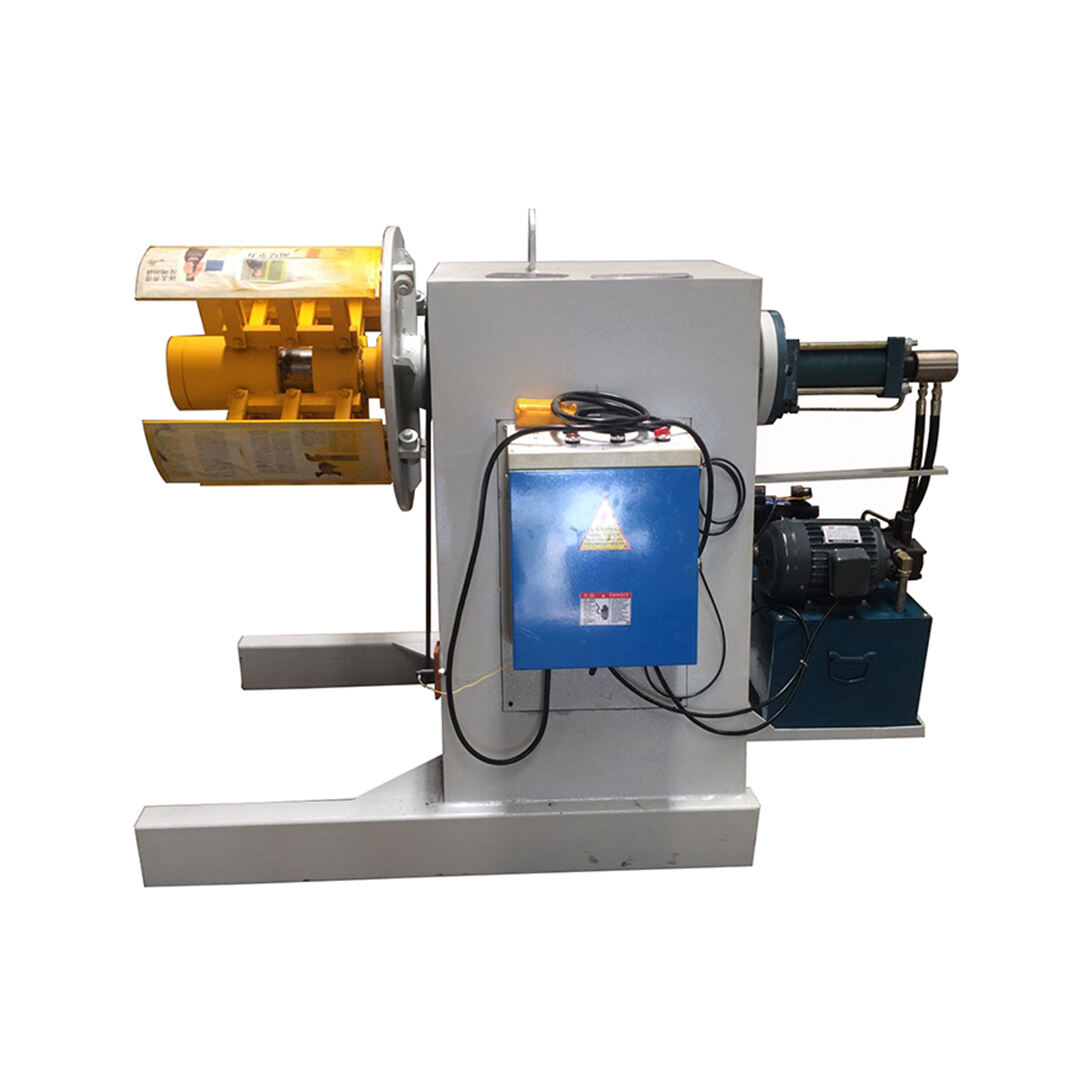

CR Light Duty Uncoiler with Contact Induction Equipment, featuring both manual and fixed material racks, Applicable Material Width: 150mm-200mm

Product Description

Product description

1. This machine features two induction modes: metal rod conduction induction and electronic micro-switch induction.

- Metal rod conduction induction: Suitable for continuous stamping processing of various hardware and electronic components.

- Electronic micro-switch induction: Suitable for continuous stamping processing of various metals and non-metals.

2. Due to its simple structure, this machine has a low failure rate.

Decoiler part

1. According to the inner diameter of the material, the outer diameter of the tile on the material rack can be adjusted arbitrarily, facilitating the insertion of the material into the rack.

2. The machine frame has a small footprint, simple structure, easy installation, and smooth operation without vibration.

3. The A-frame (material stopper frame) is made of light flat bending, welded, and then undergoes blackening treatment.

Main shaft and tile

1. The tiles are made of A3 material, undergo deburring after cutting, followed by milling of tile chamfers, then proceed to bending, drilling, and milling grooves.

2. Anti-slip nuts are used to secure all components, preventing loosening during operation and avoiding machine damage or injury incidents.

3. The main spindle screw and screw sleeve are precision machined to ensure smooth adjustment of the machine's inner and outer diameters, thus avoiding unnecessary downtime for adjustments.

Electric control box

1. Utilizing silver alloy relays, all-copper coils, flame-retardant safety bases, ensuring long-lasting durability.

2. Switches feature sliding contacts with self-cleaning function. Normally open and normally closed contacts adopt a split-coupled structure, allowing bipolar operation, with anti-rotation positioning and anti-loosening mounting pads.

3. Equipped with self-resetting flat buttons, light and agile in operation, with moderate keystroke. The contact blocks employ ketone-based composite points, providing strong conductivity and capable of carrying large currents, with a lifespan of up to 1 million cycles.

4. The control box is equipped with a forward and reverse switch, which can be used for feeding and receiving materials, greatly enhancing practicality.

Power part

1. Employing a 60-type worm gear vertical reducer, utilizing the gear speed converter, to reduce the rotation speed of the motor to the desired speed and achieve a mechanism with higher torque.

2. Using a vertical motor, with low vibration and noise. The stator part adopts pure copper coils, with a lifespan ten times that of ordinary coils. Equipped with ball bearings at both ends, resulting in low friction and temperature.

The base part

1. This equipment adopts a simplified design, enhancing site utilization, cost savings, and providing high cost-effectiveness.

2. The frame utilizes a modular assembly design, with all parts fastened using hexagon screws. The overall structure is simple, allowing assembly and equipment replacement to be carried out by general technical workers conveniently and quickly, significantly reducing maintenance costs in the later stages.

3. The frame base is made of cast material in one piece, reducing the occurrence of cracks during production. The base can be secured using anchor screws, increasing the stability during machine operation and enhancing accuracy.

Specification:

| Type | Material width (mm) | Coil.I.Dia (mm) | Coil.O.Dia (mm) | Coil Weight (kg) |

| CR-80 | 150 | 130-410 | 800 | 80 |

| CR—200 | 200 | 200-300 | 800 | 150 |