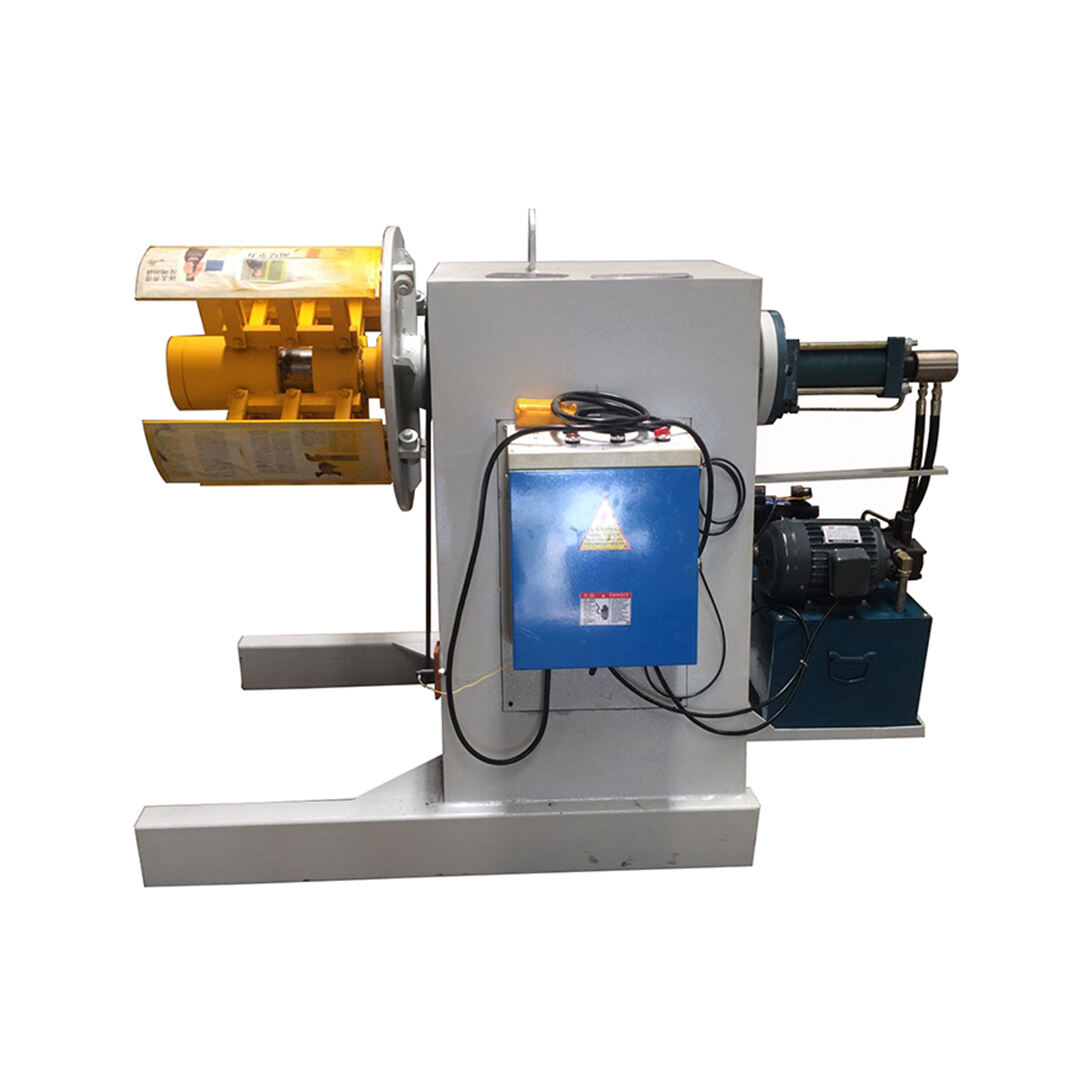

FU Flat Material Rack Series: Automatic Uncoiler/Winding Machine/Coiler and Roll Winding, Suitable for Material Widths Ranging from 130mm to 150mm

Share

Features

1.Adopt horizontal turntable feeding style, with large loading capacity, can up to 2T, the coil material can be placed overlapped to reduce the material loading times and save material changing time. It adopts two-stage speed and can adjust and track the machine working speed separately, the feeding speed can up to 0-24m/min.

2.With reasonable structure, low gravity center for discharging material.

3.Two-stage speed adjusted automatically, adopt tension switch device, the tension, the first stage and second stage can be adjusted individually, feeding smoothly.

Product Description

Description:

Maximize your floor space, reduce coil loading time, and boost production efficiency with the LIHAO Electronically Controlled Pallet Reel. Specifically designed for light gauge and narrow-width materials like tab stock for beverage cans and electrical components, the FU model excels in industries requiring precision and efficiency.

1. This machine adopts horizontal turntable feeding, with a large carrying capacity of up to 2 tons. Coil materials can be stacked to reduce the number of loading times, saving material changeover time. It employs a two-speed design with the ability to independently adjust the tracking host's operating speed. The air feeding speed can reach 0-24 meters per minute.

2. The machine has a reasonable structure with a low center of gravity, making it easy to feed materials.

3. With two-speed adjustable settings and tension switch devices, the tension level and the speeds of the first and second stages can be independently adjusted, ensuring smooth feeding.

Working principle

The disc feeder adopts a horizontal flat loading method, with the disc driven by a variable frequency controlled motor through an inductive swing rod. Materials enter the feeding roller via the guide wheel, with the speed controlled by the tensioner-driven feeding roller. As materials exceed the requirements of the press, the swing rod lowers, slowing and stopping the disc motor, while the feeding roller continues to rotate. When the disc stops and materials are tightened, the feeding roller stops, but the feeding motor continues to rotate, with the tensioner slipping to prevent material damage.

This continuous feeding cycle repeats, with the machine characterized by its robust structure, ability to stack coils, adjustable speed without steps, and easy operation, suitable for various metals, non-metals, and thin coil materials.

Specification:

| Type | FU-500 | FU-1000 | FU-2000 |

| Material width | 100mm | 120mm | 150mm |

| Material thickness | 0.1-1.2mm | ||

| Max.Pallet weight | 500kg | 1000kg | 1500kg |

| Max.Table stacking height | 400mm | 600mm | 800mm |

| Max.Pallet Dia | 600mm | 800mm | 1000mm |

| Table speed range | 3.6-24m/min | ||

| Motor | 1/2HP | 1HP | 1HP |

Standard Accessory:

Coil material head up/down controller

LED display and speed controller

Emergency stop