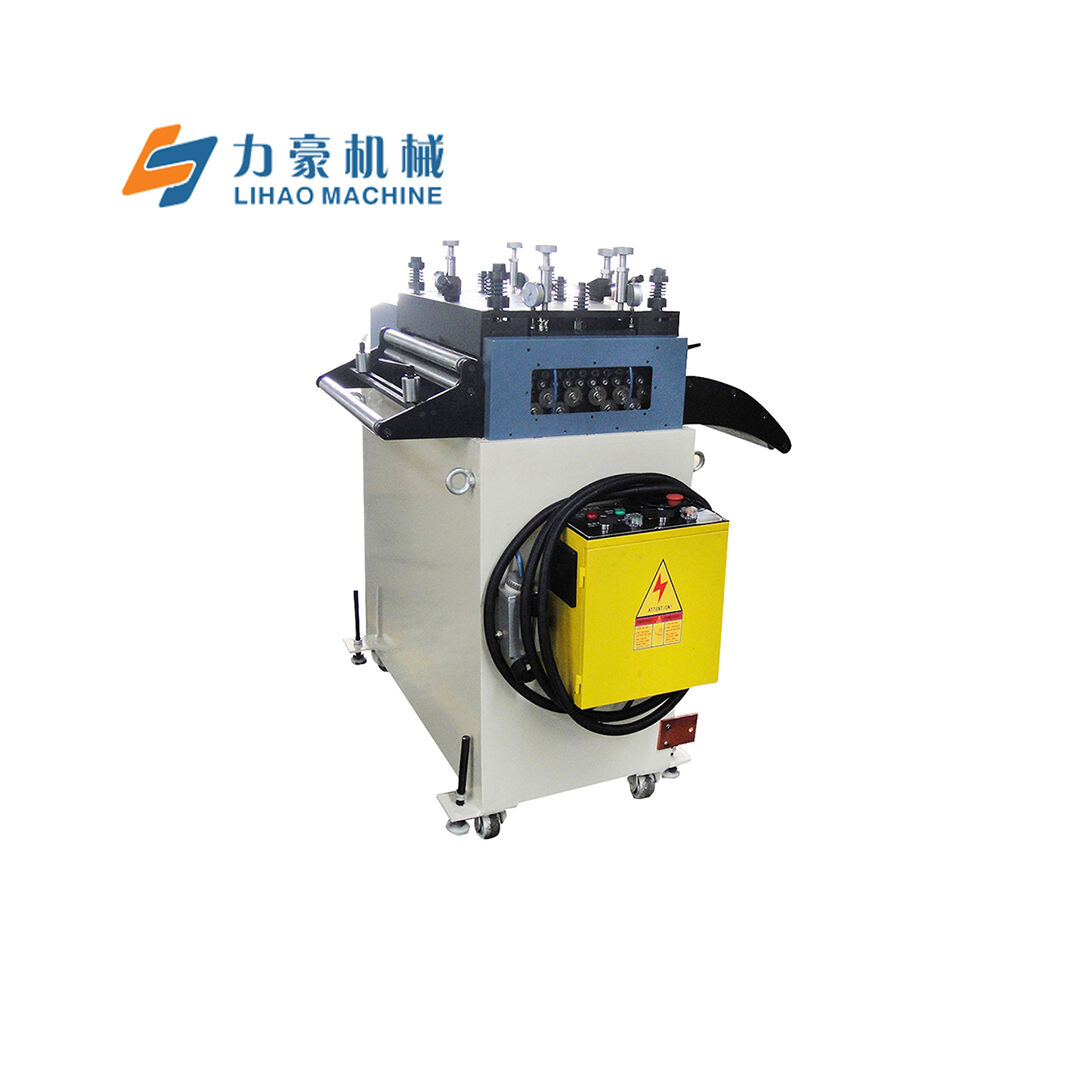

SPS Series Precision Coil Straightener Machine: Precision Metal Sheet Leveling for Material Thickness Range of 0.2mm - 1.5mm

Share

For different thickness material continuous punching use

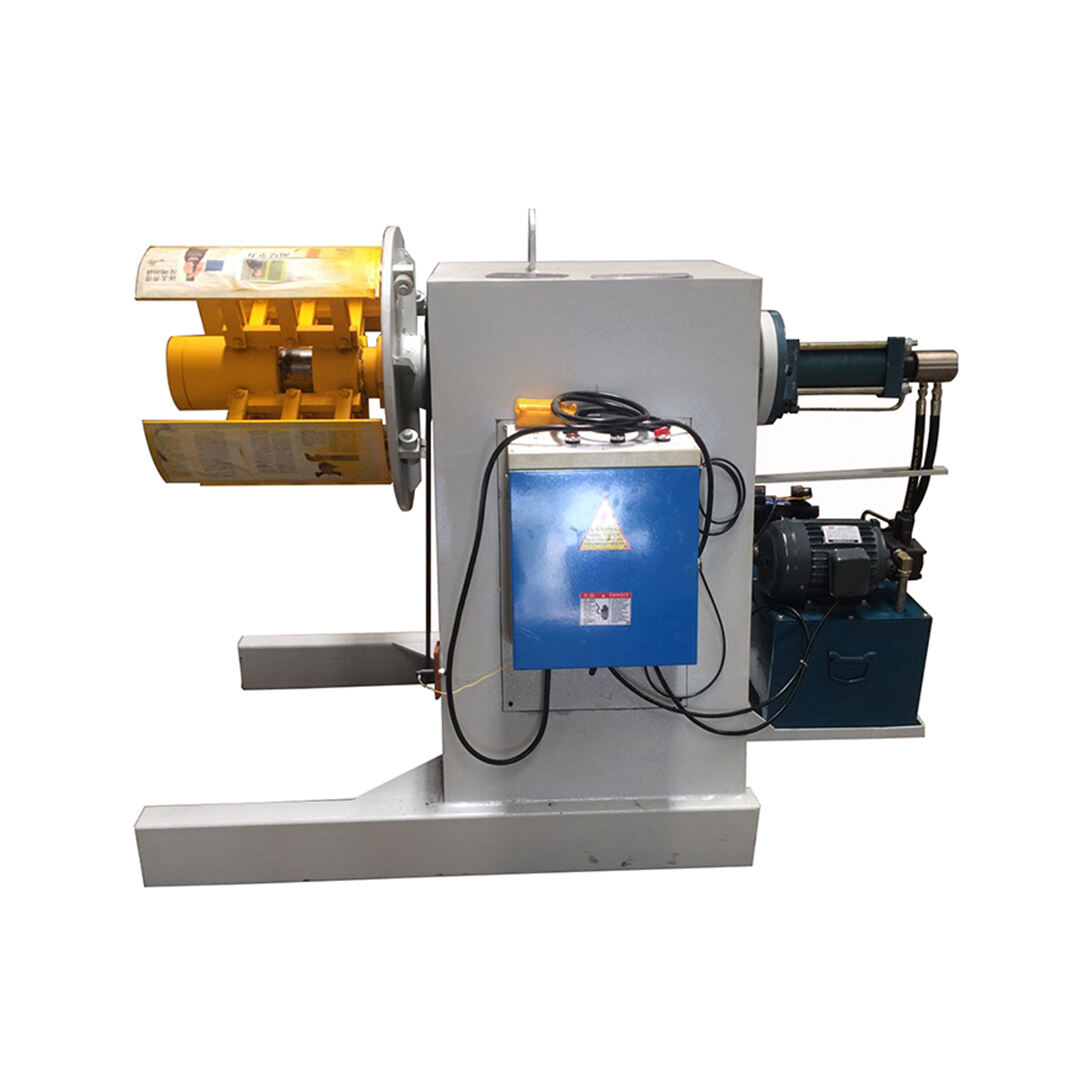

Work together with uncoiler machine for automatic production

Can be customized

Product Description

Feature:

1. This series of straightening machines is specifically designed by our company for the precise punching of thin sheet metal products. It's widely known that without leveling and stress relief, it's impossible to produce high-quality products. Therefore, the performance of the straightening machine plays a crucial role in production.

2. Both the leveling rollers and correction auxiliary rollers of this machine are made of imported SUJ2, heat-treated to HRC60°, ground after hard chromium plating to ensure uniform hard chromium layers and shape tolerances for each shaft.

3. The leveling adjustment of this machine utilizes a floating four-point balance fine adjustment device, equipped with a dial gauge, enabling rapid identification of the leveling points.

4. This machine employs universal joint transmission and a triple-gear full transmission, suitable for products with high straightening precision requirements.

5. In addition to straightening rollers, the addition of guide rollers further enhances precision by exerting rolling pressure on the material.

6. The entire machine adopts high-precision bearings and an improved lubrication system to extend its lifespan.

7. Each correction wheel of the S series precision straightening machine is equipped with leveling auxiliary wheels to ensure no bending or deformation occurs during production, thus enhancing the flatness quality of the product.

8. Both upper and lower auxiliary rollers are fixed, enhancing the rigidity of the rollers and preventing deformation under stress.

9. The triple-overlay transmission mechanism independently drives each leveling roller synchronously, reducing the accumulation of backlash tolerance caused by single gear transmission and improving the flatness requirements of the sheet metal.

10. Due to variations in material, width, and thickness, there is no uniform numerical reference. Therefore, it is advisable to first test straighten a small section of material before continuous production once the desired effect is achieved.

11. The most versatile precision straightening machine available.

Introduction:

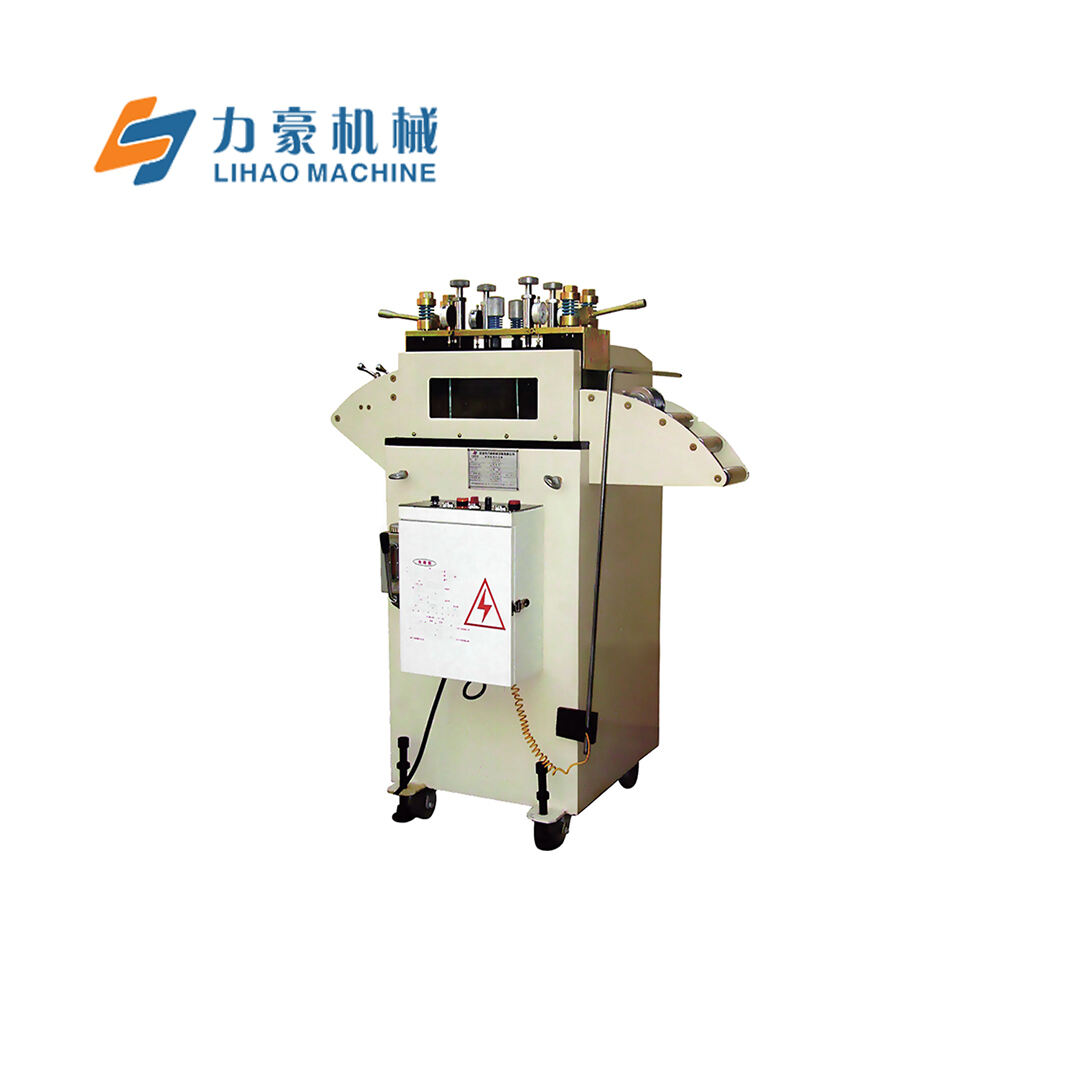

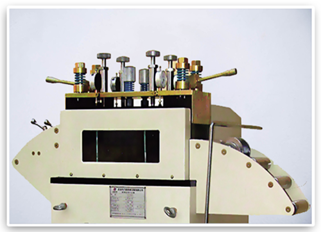

·Straightener Head

1. The machine head adopts a parallel roller design, with a total of 19 precision correction rollers, 9 on the top and 10 on the bottom.

2. Utilizing a four-point fine adjustment, it is more suitable for processing high-precision products. The infeed and outfeed employ four-point independent pressure-adjustable feeding wheel pressure, effectively preventing material deviation and deformation.

3. The material support rollers utilize non-powered galvanized rollers, formed as a whole unit, with a surface resistant to scraping and abrasion. Mechanical bearings are employed for flexible and durable rotation.

4. Cast iron material handwheels are used, treated with surface electroplating, representing the most traditional type of handwheel.

5. Protective covers are installed on both sides of the transmission section for protection, equipped with viewing windows for easy observation.

·Straightening roller

1. The straightening rollers are made of solid bearing steel, treated with a thickened electroplating process after mid-frequency treatment. The surface hardness is not less than HRC58, ensuring durability of the material.

2. GCr15 forged round steel is utilized, subjected to preheating treatment (spheroidizing annealing), followed by turning, milling, mid-frequency treatment, rough grinding for cold stabilization, precision grinding, and finally electroplating. This comprehensive process maximizes precision, concentricity, smoothness, and hardness, thereby extending the service life of the straightening rollers.

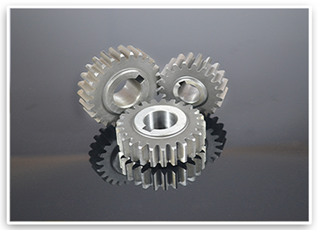

·Transmission Gear

The gear processing process includes the following steps: gear blank machining - tooth surface machining - heat treatment - tooth surface grinding. The blank is primarily forged, subjected to annealing to improve its machinability for cutting; following the gear design drawings, rough machining is performed, followed by semi-finishing, turning, rolling, and gear hobbing to achieve basic gear formation. Subsequently, heat treatment is conducted to enhance mechanical properties. Following the requirements of the design drawings, final precision machining is carried out, refining the standards and gear profiles. Through these processes, our gear achieves a grade of 6, exhibiting high wear resistance, high strength, and a long service life.

·Power Section

1. Implementing an 80-model worm gear vertical reducer, employing the gear's speed converter to lower the motor's rotation speed to the required level, thereby achieving a mechanism with increased torque.

2. Employing a vertical motor known for its minimal vibration and noise levels. The stationary rotor section features pure copper coil, boasting a lifespan ten times longer than standard coils. Ball bearings are installed at both ends, resulting in reduced friction and temperature.

·Electric control box

1. We employ silver alloy relays with all-copper coils, housed in flame-retardant safety bases, ensuring long-lasting durability.

2. Utilizing safety-protected adjustable circuitry delay relays with silver alloy contacts and multiple range dials to meet various delay requirements.

3. Switches feature sliding contacts with self-cleaning functionality. Normally open and normally closed contacts employ a separated insulation structure for bipolar operation, equipped with anti-rotation positioning and anti-loosening mounting pads.

4. We use self-resetting flat push buttons with light and nimble force, moderate keystrokes, and a modular combination structure. The contact points employ ketone-based composite points with strong conductivity, capable of carrying large currents and boasting a lifespan of up to 1 million cycles.

·Dial indicator, oil pump

1. Employing a manual grease pump for quick and effortless oil delivery. Imported oil seals are used to prevent oil leakage, while imported springs resist deformation and aging.

2. Utilizing a steel dial indicator with a precision-engineered dial face, dustproof glass, and an inner copper inset. The gauge features a copper core for stability and precise measurement.

Parameter:

| Model | SPS-150 | SPS-200 | SPS-300 | SPS-400 |

| Coil width (mm) | 150 | 200 | 300 | 400 |

| Thickness (mm) | 0.2-1.5 | 0.2-1.5 | 0.2-1.3 | 0.2-1.2 |

| Speed (m/min) | 16 | 16 | 16 | 16 |

| Motor (HP) | 1HP×4P | 2HP×4P | 2HP×4P | 3HP×4P |

| Rough roller (mm) | Φ24 | Φ24 | Φ24 | Φ24 |

| Rough roller quantity (Pcs) | 9/10(Upper/Lower) | 9/10(Upper/Lower) | 9/10(Upper/Lower) | 9/10(Upper/Lower) |

| Precision Roller (mm) | Φ30 | Φ30 | Φ30 | Φ30 |

| Precision Quantity (Pcs) | 10/11(Upper/Lower) | 10/11(Upper/Lower) | 10/11(Upper/Lower) | 10/11(Upper/Lower) |

| Dimension (m) | 1.1×0.8×1.4 | 1.1×1.3×1.4 | 1.1×1.4×1.4 | 1.1×1.5×1.4 |