What is Progressive Die and Why is it Useful?

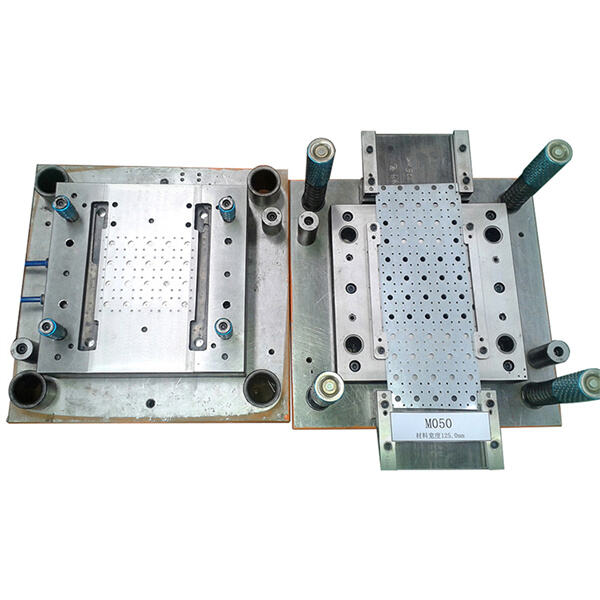

Progressive die is a tool used by manufacturers to create accurate and consistent parts for products. This Lihao progressive die tool has many advantages for companies including innovation, safety, quality, and service. We will explore these benefits and discuss how to use progressive die in your manufacturing process.

One of the biggest advantages of using progressive die is the increased efficiency and productivity in the manufacturing process. Because the Lihao steel stamping dies tool is able to create multiple parts at once, it eliminates the need for individual steps in the process and can create a higher volume of parts in a shorter amount of time.

Additionally, this tool can create complex shapes and designs with a high level of accuracy. This is due to the precise cutting and shaping processes that the tool employs, which can result in the creation of identical parts in size and shape.

The use of progressive die is an innovative way to improve the manufacturing process. By incorporating this Lihao stamping die tool, companies can create custom parts that meet the needs of their specific products. This innovation can result in a unique product and stands out in the market.

Another advantage of using progressive die is the increased level of safety in the manufacturing process. This Lihao metal stamping dies tool eliminates the need for manual labor in the creation of parts, which can reduce the risk of injury to workers. Additionally, the precise cutting and shaping processes can also improve safety by creating parts that fit together more accurately and securely.

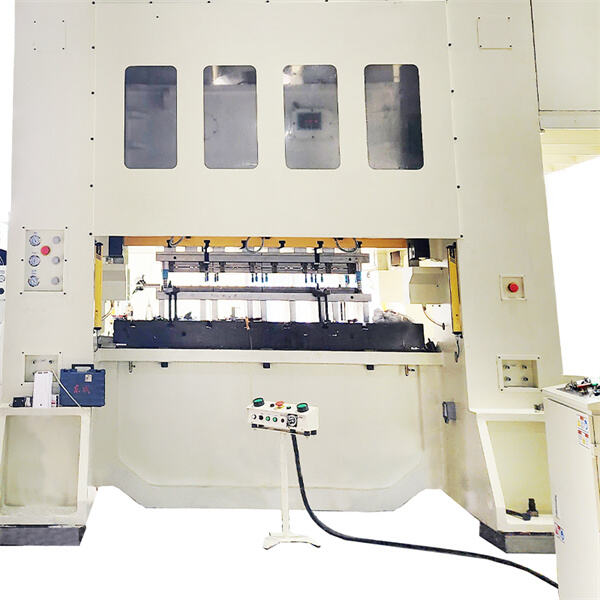

To use progressive die, the first step is to design the part that needs to be created. This Lihao die stamping press design will be used by the tool to create the part. Once the design is complete, it is sent to the tool and the manufacturing process begins.

The tool will then cut and shape the part according to the design. This will create multiple identical parts at once, stored for later use or assembled into a finished product. progressive die can be used for a variety of materials, including metal, plastic, and even paper.

Lihao Machine provides tailored solutions as well as a complete service meet with the varied needs of your customers. With a wide quantity of things like three-in-one feeders Decoiler Cum Straightener machines, NC servo feeders, and punch machines, we provide integrated services covering design production, provider and trading. Our R&dedicated D team customized options plus technical discussions making sure each solution is suitable to your unique requirements.

Our dedication to innovation, improvement and continuous reliability of merchandise and services is a constant. Our Lihao group is very skilled while offering cutting-edge solutions. We have been the real no. 1 selection for stamping automation. We place the higher value client satisfaction, providing top-quality equipment and exemplary services everytime.

With 26 several years of industry leading position Lihao Machine is a preferred supplier the domestic and worldwide markets. Our items are utilized in a wide variety of around the planet. Our customers are global through a lot more than 20 offices throughout China in addition to branch in Asia. Our technological expertise allows to provide specific solutions for assorted industries.

We excel in engineering plus robust tooling designs that minimize adjustments to your setup and for that reason reducing production that is scrap. Our progressive die offer global commissioning and training, ensuring integration that is seamless maximum performance for the realm. With in-house manufacturing plus quality parts which can be spare we guarantee minimal downtime along with maximum efficiency. Accredited with ISO9001:2000 plus EU CE we stay glued to the best standards of quality.