The Metal Slitting Machine - your spouse perfect for Cutting

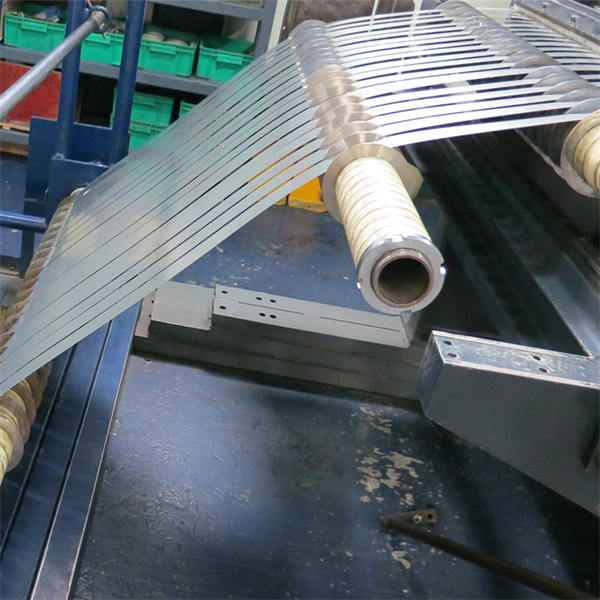

Needing of cutting steel sheets and also the Lihao slitting cutting machine with precision and rate? Then the steel device slitting your perfect partner. This revolutionary product was created to cut steel big into narrower strips at a top price, which makes it the right device for commercial usage, we are going to explore some very nice advantages of steel devices which are slitting probably the most innovations that are recent and just how to utilize them properly and effortlessly.

The steel device slitting several advantages, making it the tool go-to metalworking companies. Have a look at benefits to start thinking about:

1. High rate: The Lihao steel device slitting piece through big steel sheets at a high price, creating numerous steel strips very quickly. This capacity to effortlessly work quickly and saves some time increases efficiency.

2. Precision cutting: The steel device slitting cutting blades are manufactured to be really exact, which guarantees accurate and constant cuts. This could be specially required for companies that want top-quality and dimensions being precise their products or services.

3. Flexibility: The steel device slitting very versatile, and can cut several kinds of metals in many different thicknesses. Its adjustable cutting blades also can create widths which are various lengths of steel strips.

The steel device slitting undergone significant innovations in the last couple of years making it far better and effective same with Lihao coil slitting line. A few of these innovations consist of:

1. Laser Guided Cutting: This innovation works on the laser to steer these devices's cutting blades, causing more accurate and cuts being accurate.

2. Computerized Controls: contemporary metal slitting devices include computerized settings that make it feasible for operators to plan the apparatus for accurate cuts, making the method more efficient and decreasing the possibility of human being mistake.

3. Automatic Feeders: The metal slitting device can now have automated feeders, which eliminate the requirement for manual eating, hence increasing efficiency.

Running a metal device slitting of Lihao dangerous if appropriate security precautions aren't followed, but there are numerous precautions you will simply take to make sure usage safe

1. Always look at manufacturer's guidelines before running the unit.

2. Ensure the machine is well-maintained and all types of its components are operating precisely.

3. Wear proper safety gear, including gloves, goggles, and security ear.

4. Keep fingers and clothes loose through the product's moving components.

Employing a steel device slitting perhaps not rocket technology, nonetheless it takes a amount specific of same with Lihao slitting line machine. Here is utilizing the equipment effortlessly:

1. Prepare the steel sheet by ensuring it really is clean, flat, and free from burrs.

2. Position the steel sheet into the device's feeder, making sure it aligns making use of the blades.

3. Set the equipment's cutting width according to your desired strip size.

4. Turn in the product and monitor the technique, ensuring the apparatus just isn't under anxiety.

Lihao Machine provides tailored solutions in addition to a complete service meet various needs of clients. We offer integrated services that encompass design, manufacturing and sales. Our R&committed D team supply you with customized options and technical conversations, ensuring that every solution is suited to your unique requirements.

Lihao Machine happens to be the marketplace leader for 26 ages. It's the trusted provider both domestic and international markets. Our items are extensively utilized in many industries throughout the world. We offer our customers throughout the global world with nearly 20 offices in China and an indian branch. We offer tailored systems around many industries using our advanced technological capabilities.

Our dedication to innovation, improvement and continuous reliability of merchandise and services is a constant. Our Lihao group is very skilled while offering cutting-edge solutions. We have been the real no. 1 selection for stamping automation. We place the higher value client satisfaction, providing top-quality equipment and exemplary services everytime.

We excel in engineering plus robust tooling designs that minimize adjustments to your setup and for that reason reducing production that is scrap. Our metal slitting machine offer global commissioning and training, ensuring integration that is seamless maximum performance for the realm. With in-house manufacturing plus quality parts which can be spare we guarantee minimal downtime along with maximum efficiency. Accredited with ISO9001:2000 plus EU CE we stay glued to the best standards of quality.