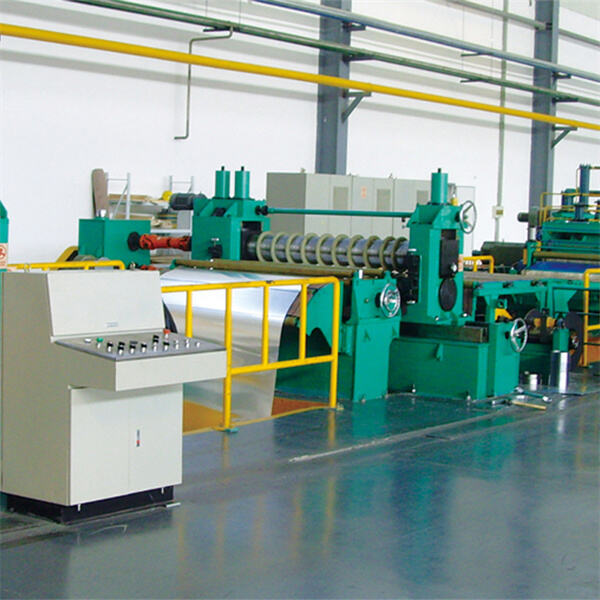

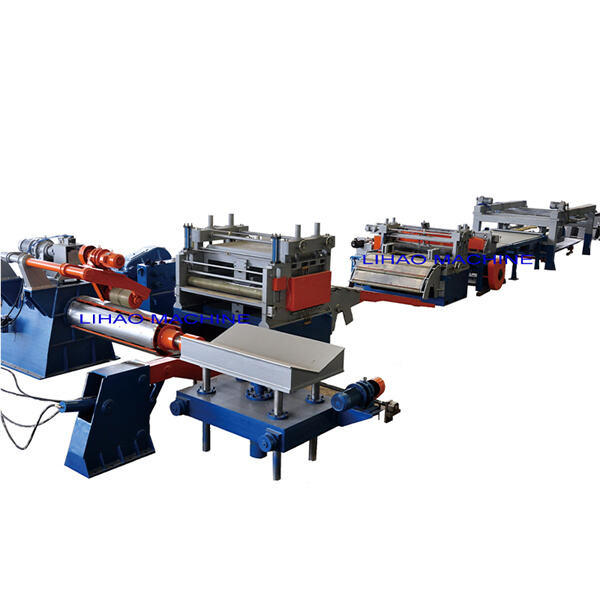

Cut to Length Lines: The Ultimate Solution in Metal Processing

As industries around the world continue to evolve and thrive, innovation and efficiency are two key aspects that businesses must focus on to stay ahead of the competition. One of the most crucial equipment that has transformed businesses in the metal processing industry is the cut to length lines. We will delve into the advantages of these lines, how to use Lihao cut to length lines, their applications, safety, and quality and service offered to customers.

Cut to length lines are industrial machines designed to process metal sheets, cut them to precise lengths, and ensure they meet the required standards. These Lihao 3 in 1 servo feeder reduce the production time, lower labor costs, and eliminate waste production. The cut to length lines will not only improve the quality of the finished product but will also enhance the industry's safety standards.

The cut to length lines have undergone massive technological advancements over the years. The new age machines allow for faster metal sheet processing and more accurate cutting, enhancing efficiency. Additionally, most of these machines are computer-controlled, allowing for automation, and reducing the machinery's downtime. The Lihao Coil Feed Line settings also allow for customization, which ensures that the metal sheets meet the specific needs of a client's production line.

Safety is a vital aspect of any industrial activity. The line operator of the cut to length lines has to be well trained and equipped with safety gear like gloves, eye protection, and ear muffs, among others. The Lihao servo feeding line design should also have safety features like emergency stop buttons and safety guards that prevent accidents and injuries in the workplace. By adhering to all the safety standards, a cut to length line becomes not just an efficient machine, but a safe one too.

Cut to length lines find their application in several industries, including automotive, construction, aerospace, and defense, to mention a few. This versatility in application makes them an essential Lihao press feeding line in any business involved in metal processing. The machines are suitable for processing various types of metals, including aluminum, steel, brass, and copper.

We have been specialists in the design and engineering of durable tooling that minimizes setup adjustments and production that is scrap is reduces. Our cut to length lines are able to deliver training that is global commissioning that ensures seamless integration and optimized performance globally. With in-house manufacturing plus quality parts that are spare we guarantee minimal interruptions plus the productivity this is certainly highest. As a ISO9001:2000 that is certified plus EU CE we abide by the high quality standards being highest.

Our dedication to quality, reliability and continual improvement of products and service is an ongoing procedure. Our Lihao team is highly skilled and offers cutting-edge solutions. We are the true number one solution in stamping automation. We place great importance in ensuring consumer satisfaction by consistently supplying the quality highest products plus services.

With 26 several years of industry leading position Lihao Machine is a preferred supplier the domestic and worldwide markets. Our items are utilized in a wide variety of around the planet. Our customers are global through a lot more than 20 offices throughout China in addition to branch in Asia. Our technological expertise allows to provide specific solutions for assorted industries.

Lihao Machine offers tailored solutions comprehensive services to fulfill various customer. We offer integrated solutions which include design, production and product sales. Our R&D team is specialized in offering modification as well as technical discussion, making certain each solution is designed to meet your requirements.