Steel Slitting Machine: An Excellent Innovation for Precision and Safety

A steel slitting machine is a revolutionary designed equipment to cut metal sheets precisely with utmost safety. This machine is widely used in the metal cutting industry because of its exceptional capabilities that add value in various metal fabrication and manufacturing processes. Steel slitting machines offer several advantages over traditional methods, and their innovative design enables optimal performance and safety standards. We will discuss the advantages of using a Lihao steel slitting machine, its innovation, safety, use, how to use it, service, quality, and applications.

Steel slitting machines offer several advantages over traditional cutting methods. Firstly, they provide precision cut with exact tolerances that ensure the end product's high quality. Secondly, they are faster and can handle a more significant volume of metal cutting tasks than traditional equipment. Thirdly, Lihao slitting machine offers flexibility and versatility, enabling them to cut various metal thicknesses and types. Fourthly, steel slitting machines are cost-effective and efficient in terms of energy consumption. Finally, they minimize material wastage and increase material yield, which translates to reduced operational costs.

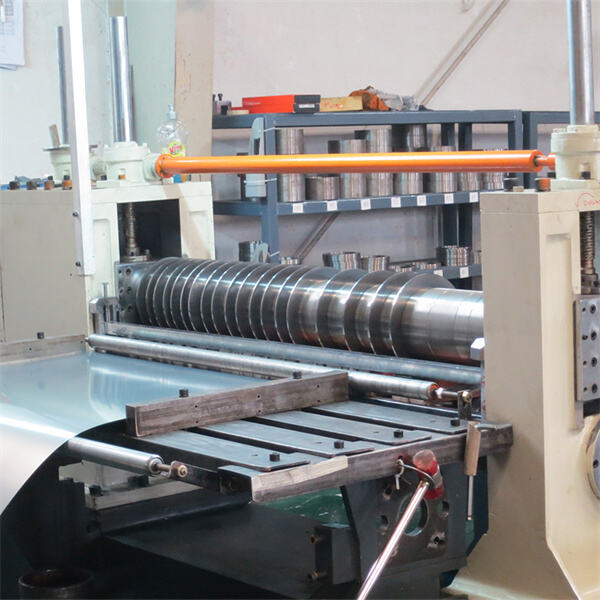

Innovation is at the forefront of steel slitting machine technology. The Lihao slitting cutting machine is continually evolving to meet the increasing metal cutting demands, environmental standards, and safety regulations. The latest steel slitting machine designs are compact, user-friendly, and highly efficient. They incorporate innovative technologies, such as servo motors, touch screen control panels, and thermal cameras, which improve machine performance, reduce downtime, and ensure precision cutting. Steel slitting machines also feature advanced safety mechanisms that prevent accidents and operator injuries. Some of these safety measures are the installation of light curtains, emergency stop buttons, and automatic blade positioning.

Safety is paramount in any modern-day industrial setting, and the metal cutting industry is not an exception. Steel slitting machines should meet strict safety standards to protect operators from harm. The Lihao steel coil slitting machine comes with safety features such as automatic roll discharge systems, overload protection, blade guards, and safety interlocks. Operators should also ensure they use personal protective equipment, such as gloves, earplugs, and safety glasses.

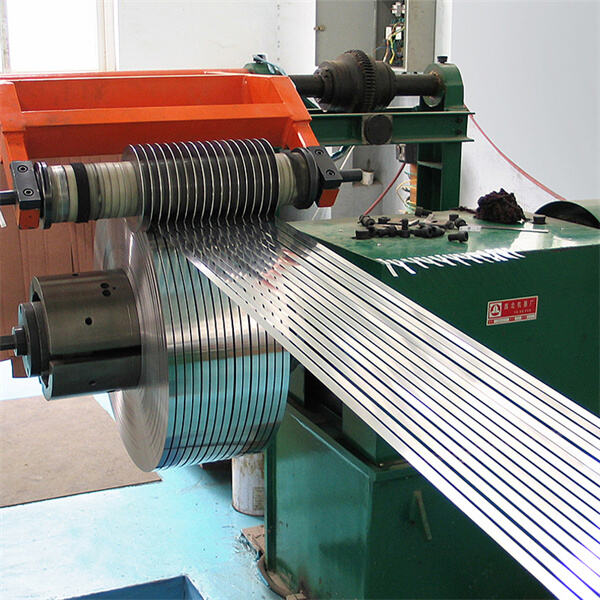

Using a steel slitting machine is uncomplicated. The first step is to power the machine, ensuring that all safety features are working accurately. Secondly, load the metal coil onto the uncoiler, ensuring that it's properly secured. The next step is to thread the material through the slitting head and adjust the blade spacing to the required thickness. Lastly, set the desired coil width and speed, and start the Lihao coil slitting machine.

Lihao Machine is a huge business is leading the industry because 1996. It is only a trusted supplier both the national and international markets. Our products are trusted in lots of industries throughout the world. All over the globe with over twenty offices in China and an overseas branch in Asia We provide our customers. We offer tailored solutions throughout various industries with this robust technological capabilities.

Our dedication to innovation, improvement and continuous reliability of merchandise and services is a constant. Our Lihao group is very skilled while offering cutting-edge solutions. We have been the real no. 1 selection for stamping automation. We place the higher value client satisfaction, providing top-quality equipment and exemplary services everytime.

We excel in engineering plus robust tooling designs that minimize adjustments to your setup and for that reason reducing production that is scrap. Our steel slitting machine offer global commissioning and training, ensuring integration that is seamless maximum performance for the realm. With in-house manufacturing plus quality parts which can be spare we guarantee minimal downtime along with maximum efficiency. Accredited with ISO9001:2000 plus EU CE we stay glued to the best standards of quality.

Lihao Machine provides tailored solutions comprehensive service meet up with the diverse needs of customers. Offering a selection of products, including 3 in 1 feeders Decoiler Cum Straightener machines, NC servo feeders, and punch machines, we offer incorporated services covering production design purchases, service plus trading. Our R&D team is dedicated to ensuring that the option is had by you of customizing your choices and technical discussions making sure that every solution is perfectly tailored to your requirements.