Discovering the world of coil slitting machines

Are you curious about coil slitting machines and what they do? You've come to the right place. We'll discuss what a Lihao coil slitting machine is, how it works, and its advantages. We'll also go over safety measures to ensure your well-being when using it and the different ways you can use it. Plus, we'll delve into the innovation and quality behind these machines and the services they offer. So, let's get started.

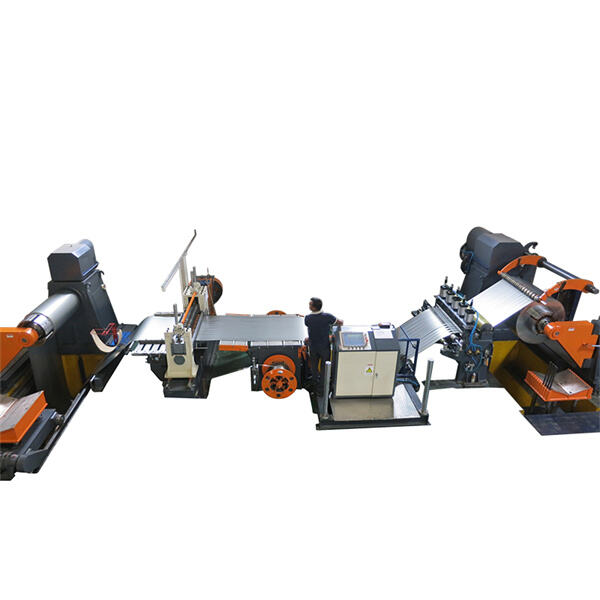

A coil slitting machine is a unique machine that divides metal coils into multiple thinner strips of various widths. They are mostly used in the metalworking industry to serve the specific demands of various businesses that require metal components in specific shapes and sizes. This Lihao slitting machine offers considerable advantages over traditional methods of cutting metal. They not only save time but also provide a cleaner, more precise cut, resulting in more efficient manufacturing processes. It's an ideal solution if you require a high level of accuracy in metal cutting.

There are many benefits to using a Lihao steel coil slitting. Some of them include:

1. Time-saving

2. Increased efficiency and productivity

3. High accuracy and consistency

4. Reduced material waste

5. Improved Safety

At the heart of modern coil slitting machines are the latest manufacturing techniques that incorporate cutting-edge technology. Lihao coil cutting machine uses advanced software and controls that can increase the accuracy and responsiveness of the machine's operation. Modern coil slitting machines are also designed to be more user friendly, efficient, and convenient for the operator. They are built with the latest technology and feature the latest advancements to make manufacturing processes more efficient than ever before.

Safety is a top priority when working with machinery. coil slitting machines are designed with safety in mind. Lihao slitting line machine comes with built-in safety features, such as sensors and guards, to ensure safe operation. It is imperative to follow safety guidelines when using a coil slitting machine. For example, when operating the equipment, it's essential to wear protective gear, such as goggles and gloves, to prevent injury.

Lihao Machine provides tailored solutions in addition to a complete service meet up with the varied needs of your customers. Offering a number of products like three-in-one feeders Decoiler Cum Straightener machines, NC servo feeders, plus punch machines, we offer complete service that cover manufacturing, design, sales, service, and trading. Our R&devoted D team customization options and technical discussions, ensuring that every product is customized to fulfill your individual needs.

Lihao Machine happens to be the marketplace leader for 26 ages. It's the trusted provider both domestic and international markets. Our items are extensively utilized in many industries throughout the world. We offer our customers throughout the global world with nearly 20 offices in China and an indian branch. We offer tailored systems around many industries using our advanced technological capabilities.

We are specialists in engineering and robust design of tools, which helps in reducing set-up adjustments and scrap production that is reducing. Our coil slitting machine offer worldwide training and commissioning to make sure performance this is certainly optimal seamless integration across the planet. We guarantee maximum efficiency plus minimized downtime by providing in-house production, high-quality spare parts, and support which is ongoing. As a ISO9001:2000 that is certified and EU CE We uphold the best standards of quality.

Our dedication to reliability, innovation and continuous enhancement of products and services is a consistent. Our highly Lihao ensures cutting-edge solutions that produce us the top choice for equipment for stamping automation. We place a high priority in ensuring customer satisfaction by consistently providing the quality solutions being highest and services.

Using a coil slitting machine can seem intimidating at first, but it's an uncomplicated process when you know what you are doing. Below are some basic steps to follow when using a coil slitting machine:

1. Prepare the coil by feeding it into the Lihao slitting cutting machine and securing it in place.

2. Set the machine's parameters for the required strip widths.

3. Turn on the machine and monitor the operation to ensure its running smoothly.

4. Once all strips have been cut, remove the finished product from the machine.

5. Inspect the finished product for any defects or errors.

Coil slitting machine manufacturers offer a range of services, including installation, maintenance, and repairs. Manufacturers will also provide on-site training for their Lihao metal slitting machine, allowing operators to become familiar with the machine's operation. They offer technical support and provide replacement parts to keep your machine operating at its best.

Quality is of utmost importance to coil slitting machine manufacturers. Lihao steel slitting machine uses high-quality materials that meet the standards set by the industry. Manufacturers utilize the latest technology and equipment for quality assurance, ensuring that every product that leaves their facility meets or exceeds expectations. The end result is a superior product that operates efficiently and provides consistent results.